What is “C64200” Material?

C64200, also known as aluminum bronze, is a high-strength alloy that is primarily composed of copper, aluminum, and iron. It is often used in industrial applications that require excellent wear resistance and good mechanical properties.

One of the key benefits of C64200 is its high tensile and yield strength, which make it an ideal material for use in heavy-duty applications. It also exhibits good corrosion resistance, making it a popular choice for marine and offshore applications.

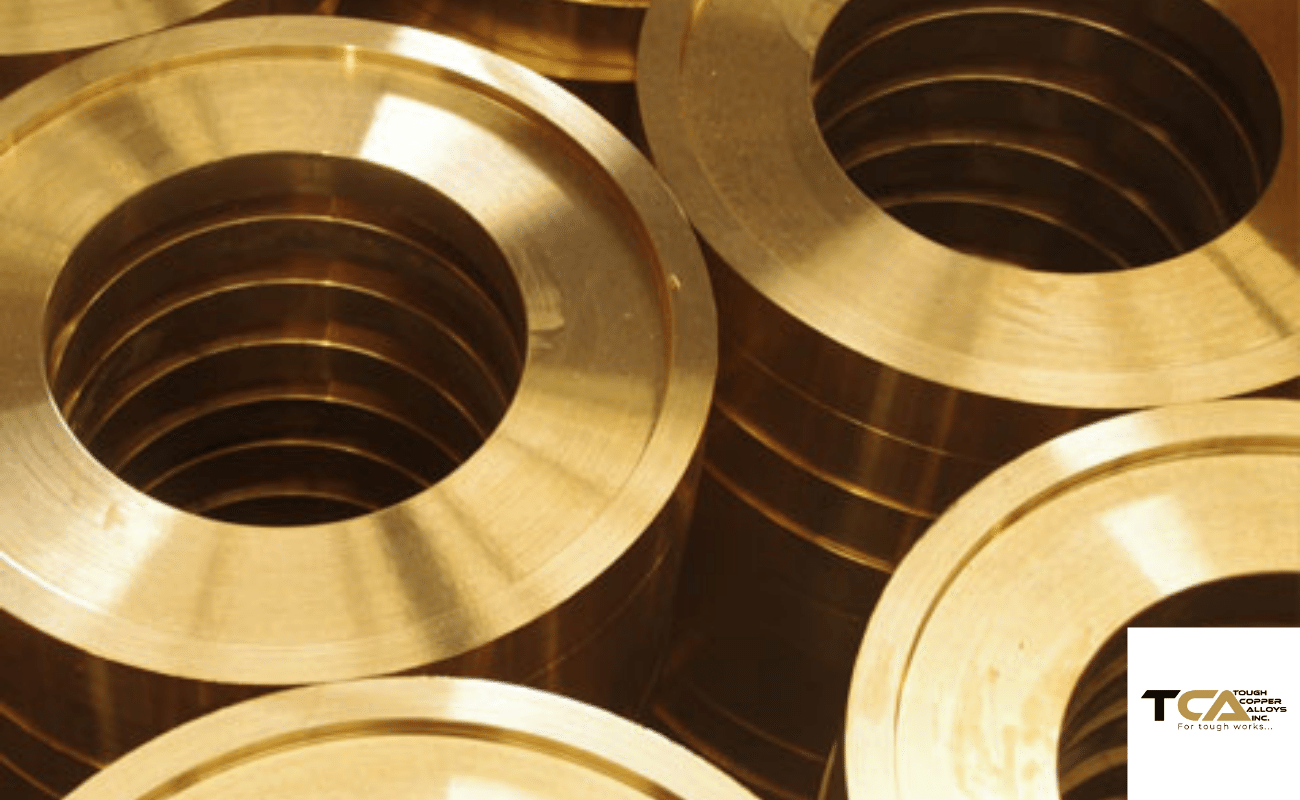

C64200 is a versatile material that can be easily formed and machined into various shapes and sizes. It is commonly used in the production of gears, bushings, bearings, and other industrial components that require high strength and durability.

In addition to its mechanical properties, C64200 also exhibits good thermal conductivity, making it an excellent choice for heat transfer applications. It is often used in the manufacturing of heat exchangers and other thermal management components.

C64200 is also a good choice for applications that require resistance to high temperatures and thermal shock. Its high-strength properties allow it to withstand high stress and strain without deformation or cracking.

Overall, C64200 is a reliable and durable material that is suitable for a wide range of industrial applications. Its excellent mechanical and thermal properties, combined with its corrosion resistance and formability, make it a popular choice among engineers and manufacturers.

Application Areas & Industries

C64200, also known as aluminum bronze, is a high-strength alloy that is well-suited for a range of industrial applications. Its excellent mechanical properties make it a popular choice for applications that require strength, durability, and wear resistance. Here are some of the key application areas and industries where C64200 is commonly used:

- Marine Industry: C64200 is widely used in the marine industry for applications such as propeller shafts, seawater piping systems, and valve components. Its excellent corrosion resistance and high strength make it well-suited for use in harsh marine environments.

- Aerospace Industry: In the aerospace industry, C64200 is used for critical applications such as landing gear components, engine parts, and missile components. Its high strength, corrosion resistance, and wear resistance make it an ideal material for use in aerospace and defense applications.

- Manufacturing Industry: C64200 is also commonly used in the manufacturing industry for applications such as gears, bushings, bearings, and other industrial components. Its excellent wear resistance and dimensional stability make it a popular choice for applications that require high durability and precise tolerances.

- Electrical and Electronic Industry: In the electrical and electronic industry, C64200 is often used for connectors, contacts, and other components that require high conductivity and durability.

Overall, C64200 is a versatile material that offers excellent mechanical properties and is well-suited for a range of industrial applications. Its high strength, wear resistance, and corrosion resistance make it a reliable and durable material that can withstand harsh operating conditions.

Common Fabrication Processes

C64200 is a copper alloy containing a high percentage of lead, known for its excellent machinability, high corrosion resistance, and good electrical conductivity. This unique material finds applications in various industries, including electrical components, plumbing fixtures, and marine hardware. Here are some common fabrication processes for C64200:

- Casting: In this process, molten metal is poured into a mold and allowed to solidify. Casting is ideal for producing large and complex parts, making it a popular choice for C64200. However, it can result in porosity and other defects that can impact mechanical properties.

- Forging: This process involves shaping the metal by applying pressure to it while it’s still in a solid state. Forging can produce parts with excellent strength and durability, but it’s not as effective at creating complex shapes as casting.

- Machining: This process removes material from a workpiece using cutting tools. It’s ideal for creating precise shapes and tolerances, making it a popular choice for C64200 parts that require high accuracy. However, machining can be time-consuming and costly, especially for large or complex parts.

In conclusion, C64200 is a versatile copper alloy that can be fabricated using a variety of processes, each with its own strengths and weaknesses. The choice of process will depend on the specific requirements of the application. If you have any questions or need more information about the fabrication processes of C64200, please contact us today.

Chemical Composition

C64200, also known as aluminum bronze, is a copper alloy that contains a high percentage of lead, as well as small amounts of iron, nickel, manganese, and aluminum. The exact chemical composition of C64200 can vary slightly depending on the specific manufacturing process used, but the following table provides a general overview:

| Element | Percentage |

|---|---|

| Copper | 76.0-79.0 |

| Lead | 2.5-3.5 |

| Iron | 0.10 max |

| Nickel | 0.30 max |

| Manganese | 0.50 max |

| Aluminum | 8.5-9.5 |

| Zinc | 2.5-3.5 |

| Tin | 0.20 max |

| Others | 0.50 max |

The high percentage of copper in C64200 provides excellent electrical and thermal conductivity, while the addition of lead improves its machinability. The presence of aluminum and other elements helps to enhance the alloy’s mechanical properties, including strength, hardness, and corrosion resistance.

Overall, the chemical composition of C64200 makes it a highly versatile copper alloy that can be used in a wide range of applications, including electrical components, plumbing fixtures, and marine hardware. If you need more information about the chemical composition of C64200 or have any other questions, please contact us today.

Physical Properties

C64200 is a copper alloy that is well-known for its excellent physical properties. These properties make it a popular choice for a variety of applications, including electrical components, plumbing fixtures, and marine hardware. In this article, we will take a closer look at the physical properties of C64200.

Density: C64200 has a density of approximately 8.47 g/cm3, which is slightly higher than that of pure copper. This makes it a relatively dense material that is ideal for applications that require high mass or weight.

Melting Point: The melting point of C64200 is around 1040°C (1900°F), which is similar to that of other copper alloys. This high melting point makes it suitable for use in applications that require high-temperature resistance.

Thermal Conductivity: C64200 has a high thermal conductivity, which means it can easily transfer heat. This property makes it an ideal material for applications that require efficient heat transfer, such as heat exchangers.

Electrical Conductivity: C64200 has excellent electrical conductivity, which makes it a popular choice for electrical components. It has a conductivity of approximately 24% IACS (International Annealed Copper Standard).

Magnetic Properties: C64200 is a non-magnetic material, which means it does not have any magnetic properties. This property makes it suitable for applications where magnetic interference needs to be minimized.

Corrosion Resistance: C64200 has excellent corrosion resistance, particularly in marine environments. This makes it a popular choice for marine hardware, such as propellers and ship fittings.

In conclusion, C64200 is a versatile copper alloy that boasts excellent physical properties. Its high density, high melting point, high thermal conductivity, excellent electrical conductivity, non-magnetic properties, and corrosion resistance make it an ideal material for a wide range of applications. If you have any questions about the physical properties of C64200 or its suitability for your specific application, please contact us today.

Below is a table summarizing the physical properties of C64200:

| Property | Value |

|---|---|

| Density | 8.47 g/cm3 |

| Melting Point | 1040°C (1900°F) |

| Thermal Conductivity | High |

| Electrical Conductivity | 24% IACS |

| Magnetic Properties | Non-Magnetic |

| Corrosion Resistance | Excellent |

Fabrication Properties

C64200 is a copper alloy that has several favorable fabrication properties, making it a versatile material for a variety of applications. Here are some of its notable fabrication properties:

- Machinability: C64200 has excellent machinability, meaning it can be easily machined using standard cutting tools. This property allows for the creation of precise shapes and tolerances, making it ideal for creating parts with intricate geometries.

- Formability: C64200 has good formability, making it well-suited for applications that require the material to be bent, stamped, or formed. It can be easily cold-formed, and it can also be hot-formed at temperatures between 750 and 900 degrees Fahrenheit.

- Weldability: C64200 has excellent weldability, meaning it can be easily welded using standard welding techniques such as TIG, MIG, and spot welding. It can also be brazed using silver brazing alloys, creating a strong bond between the two materials.

- Stress corrosion cracking resistance: C64200 is highly resistant to stress corrosion cracking, making it an excellent choice for marine and industrial applications where exposure to harsh environments is common.

Overall, the fabrication properties of C64200 make it an attractive material for a wide range of applications. Its ease of machining, good formability, weldability, and resistance to stress corrosion cracking make it a reliable and versatile material for creating precise shapes and parts.

Applicable Specifications

C64200 is a copper alloy widely used in various industrial applications due to its unique physical and mechanical properties. To ensure its proper use, it is important to be aware of the applicable specifications for this material.

The following is a list of common specifications for C64200:

ASTM B301: This specification covers the requirements for copper alloy bars, rods, and shapes, including C64200 and other similar copper alloys.

SAE J461: This specification covers the chemical and mechanical properties of copper alloys, including C64200, and provides guidance on their selection and use in different applications.

Industry-specific specifications: Depending on the intended use of the material, C64200 may also be subject to specifications set by organizations such as ASME or API.

Adhering to these specifications is crucial to ensure the quality, reliability, and compatibility of C64200 in various industrial applications. It is always important to consult the appropriate specification before selecting or using C64200 material.

Thermal Properties

C64200, also known as aluminum bronze, is a copper alloy that boasts excellent thermal properties, making it ideal for use in high-temperature applications. Some of the thermal properties of C64200 include:

High Thermal Conductivity: With a thermal conductivity of 37.7 W/(m-K), C64200 has a higher thermal conductivity than many other copper alloys. This property allows it to transfer heat quickly and efficiently, making it an excellent choice for heat-intensive applications such as heat exchangers and electrical conductors.

Low Coefficient of Thermal Expansion: C64200 has a low coefficient of thermal expansion, which means that it can withstand significant temperature fluctuations without undergoing thermal stress or thermal shock. This property allows it to maintain its shape and integrity even in high-temperature environments, making it well-suited for use in various industrial applications.

High Melting Point: C64200 has a relatively high melting point of around 1025°C (1877°F), which makes it suitable for use in applications that involve exposure to high temperatures.

In addition to its exceptional thermal properties, C64200 also has good corrosion resistance and mechanical properties, making it a versatile and reliable material for various industrial applications.

In summary, C64200 is a copper alloy that exhibits excellent thermal properties, including high thermal conductivity, low coefficient of thermal expansion, and high melting point, making it an ideal choice for high-temperature applications. Its good corrosion resistance and mechanical properties further enhance its suitability for various industrial applications.

Typical Uses of “C64200”

C64200, also known as aluminum bronze, is a copper alloy that is well-suited for a variety of industrial applications due to its unique physical and mechanical properties. Some of the typical uses of C64200 include:

- Marine Engineering: C64200 is commonly used in marine applications due to its excellent resistance to corrosion, erosion, and biofouling. It is often used for propellers, valve bodies, and other components in marine vessels.

- Electrical Components: C64200 has excellent electrical conductivity and thermal properties, making it a popular choice for electrical components such as connectors, switches, and circuit breaker parts.

- Aerospace: C64200 is used in the aerospace industry for various applications such as bushings, bearings, and gears. Its high strength, good fatigue resistance, and excellent thermal properties make it ideal for use in aircraft engines and landing gear components.

- Industrial Equipment: C64200 is used in various industrial equipment such as heat exchangers, pump components, and high-pressure hydraulic systems. Its high strength, good wear resistance, and excellent thermal properties make it ideal for use in demanding industrial environments.

- Automotive: C64200 is used in automotive applications such as bushings, bearings, and valve guides. Its excellent wear resistance, good fatigue strength, and high thermal stability make it ideal for use in engine components that are subjected to high temperatures and stress.

In summary, C64200 is a versatile copper alloy that finds applications in a wide range of industries, including marine engineering, electrical components, aerospace, industrial equipment, and automotive. Its unique combination of physical and mechanical properties makes it well-suited for demanding applications that require high strength, durability, and thermal stability.

Equivalents

C64200 is a copper alloy that exhibits excellent thermal properties, making it a popular choice for various high-temperature applications. However, in some cases, C64200 may not be readily available or suitable for a particular application. In such cases, it is important to consider alternative copper alloys that have similar properties to C64200.

Here are some copper alloys that are equivalent to C64200 in terms of their thermal properties:

- C61400: This copper alloy has a similar thermal conductivity to C64200 and is also known for its excellent corrosion resistance. It is often used in marine and chemical processing applications.

- C63000: Also known as AMS 4640, this high-strength copper alloy has a high thermal conductivity and a low thermal expansion coefficient, making it suitable for applications where both properties are important.

- C71500: This copper-nickel alloy has a high thermal conductivity and excellent resistance to corrosion and biofouling, making it ideal for use in seawater applications.

- C70600: Another copper-nickel alloy, C70600 has a similar thermal conductivity to C64200 and is often used in heat exchangers and condenser tubes in power plants and desalination plants.

- C77000: This copper-nickel-zinc alloy has a high thermal conductivity and excellent resistance to corrosion in seawater and other harsh environments. It is often used in marine and offshore applications.

When selecting an equivalent copper alloy to C64200, it is important to consider the specific properties required for the application, such as thermal conductivity, thermal expansion coefficient, corrosion resistance, and mechanical properties. By choosing an appropriate equivalent alloy, it is possible to achieve the same level of performance as C64200 in a variety of high-temperature applications.

Mechanical Properties of “C64200”

C64200 (Aluminum Bronze) is a highly durable and strong material that is ideal for use in various industrial applications. Here are the key mechanical properties of C64200:

Tensile strength: C64200 has a high tensile strength of 655 MPa (95,000 psi), making it a reliable material for applications that require strength and durability.

Yield strength: With a yield strength of 275 MPa (40,000 psi), C64200 can withstand stress without permanent deformation, indicating its ability to maintain its shape under stress.

Elongation at break: C64200 has an elongation at break of 17%, indicating that it can undergo deformation without fracturing.

Hardness: The Brinell hardness of C64200 is 190, and the Rockwell B hardness is 91, making it a relatively hard and wear-resistant material.

Modulus of elasticity: With a modulus of elasticity of 117 GPa (17,000 ksi), C64200 has good stiffness and can maintain its shape under stress.

These mechanical properties make C64200 an ideal material for various industrial applications, including bearings, gears, valve components, and marine hardware.

| Property | Value |

|---|---|

| Tensile Strength | 655 MPa (95,000 psi) |

| Yield Strength | 275 MPa (40,000 psi) |

| Elongation at Break | 17% |

| Hardness, Brinell | 190 |

| Hardness, Rockwell B | 91 |

| Modulus of Elasticity | 117 GPa (17,000 ksi) |

Please note that the mechanical properties of C64200 may vary depending on the specific production process and testing method used. Therefore, it’s important to refer to appropriate standards and specifications for detailed information on the mechanical properties of C64200.