What is “C86500” Material?

C86500 bronze is a popular choice for many industries due to its unique combination of properties. Its high silicon content provides it with increased strength, hardness, and wear resistance compared to other bronze alloys. It also offers excellent corrosion resistance, making it an ideal material for use in harsh environments such as marine applications.

The composition of C86500 bronze typically includes 59-62% copper, 3-7% silicon, 0.05% max iron, 0.05% max manganese, 0.05% max nickel, and the remainder made up of zinc. This alloy is also known as “silicon bronze,” “high-strength bronze,” or “engineered bronze.” The high silicon content of C86500 bronze provides it with unique properties that make it an excellent material for various applications.

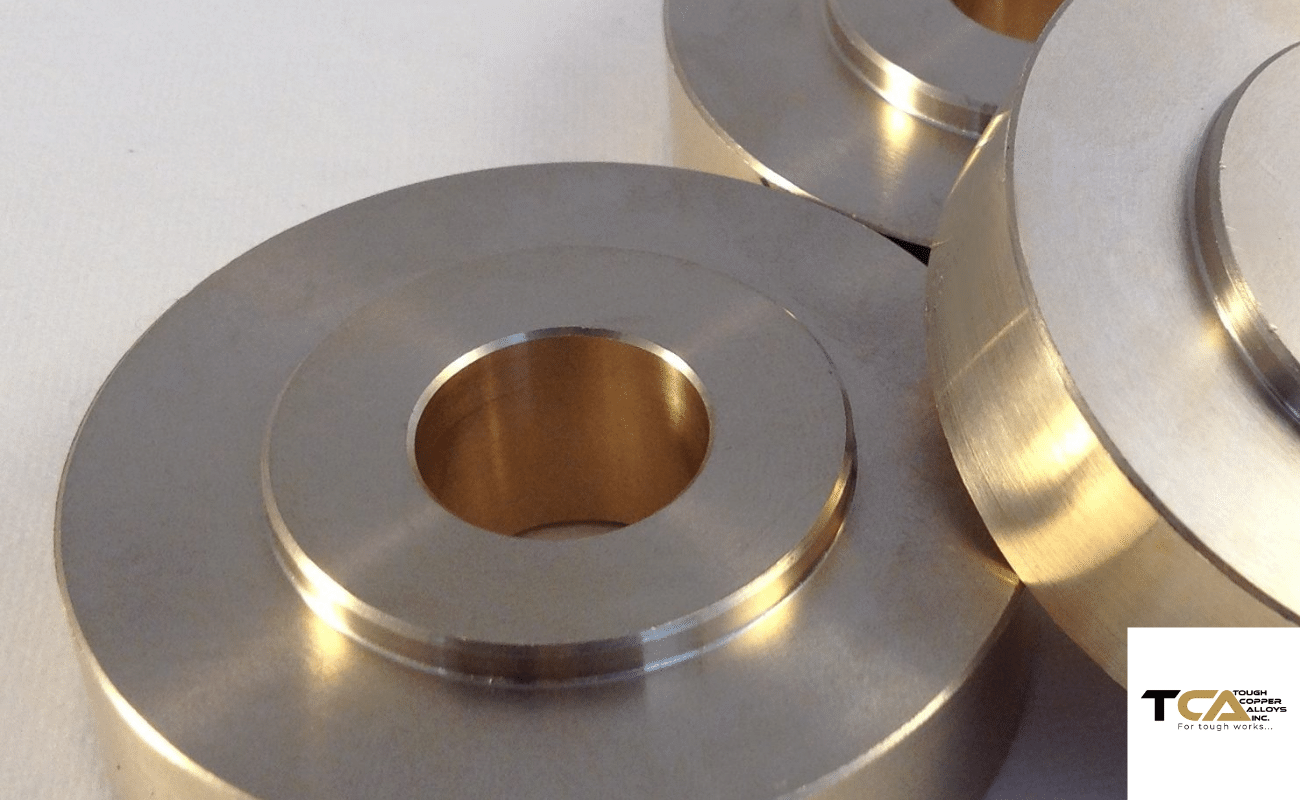

One of the main advantages of C86500 bronze is its high strength and durability. It is often used in applications that require high-strength materials, such as bushings, bearings, gears, and fittings. Its excellent wear resistance also makes it a popular choice for components that are subject to friction and wear, such as valve stems and pump parts. Additionally, its high corrosion resistance makes it suitable for marine applications, such as shipbuilding and marine hardware.

C86500 bronze is also highly machinable and weldable, which makes it a popular choice for fabrication processes. It can be cast, forged, or extruded into various shapes and sizes, which makes it a versatile material that can be customized to meet specific manufacturing needs. Its machinability also makes it easier to work with than other materials, which can save time and money during the manufacturing process.

In summary, C86500 is a high-silicon bronze alloy that offers excellent strength, corrosion resistance, and durability. Its unique properties make it a popular choice for a wide range of applications, from marine hardware to pump parts. Its high machinability and weldability also make it an ideal material for fabrication processes.

Application Areas & Industries

C86500, also known as high-silicon bronze, is a versatile bronze alloy that has a variety of applications in many industries. Its high strength, excellent wear resistance, and exceptional corrosion resistance make it an ideal material for many different types of components and structures.

Marine Hardware: This alloy’s excellent corrosion resistance makes it ideal for use in saltwater environments, which is why it is commonly used in shipbuilding and other marine applications. It is often used to make components such as propellers, rudder bearings, and shipbuilding fittings.

Pump and Valve Manufacturing Industry: This alloy’s high strength and wear resistance make it an excellent material for making pump parts and valve stems that are subject to high stress and wear. C86500 bronze can also be used to make bushings, bearings, and other components that require high strength and durability.

Construction Industry: where its strength and corrosion resistance make it ideal for building structures that need to withstand harsh weather conditions. This alloy is often used to make roof tiles, rainwater goods, and other architectural features.

The Electrical and Electronics Industry: Its high electrical conductivity and low thermal expansion coefficient make it an ideal material for making electrical contacts, connectors, and other components that require high electrical conductivity.

Transportation Industry: C86500 bronze is used to make components such as gears, bearings, and bushings. Its high strength and wear resistance make it an excellent material for these applications, especially in heavy-duty applications such as trucks and trains.

In summary, C86500 is a versatile bronze alloy that finds applications in various industries due to its high strength, excellent wear resistance, and exceptional corrosion resistance. It is commonly used in marine hardware, pump and valve manufacturing, construction, electrical and electronics, and transportation industries. Its unique properties make it a popular choice for components and structures that require high strength, durability, and corrosion resistance.

Common Fabrication Processes

C86500, also known as high-silicon bronze, is a popular bronze alloy that has many fabrication advantages. Its unique properties, such as high strength, wear resistance, and corrosion resistance, make it an ideal material for many applications. There are several common fabrication processes used to work with C86500 bronze, including casting, forging, and extrusion.

Casting: It involves pouring molten metal into a mold, which then cools and solidifies into the desired shape. This process can produce parts of various shapes and sizes with excellent precision and detail. C86500 bronze is highly castable and can be used to produce intricate designs and shapes that are difficult to achieve with other materials.

Forging: This process involves shaping the material by applying force with a hammer or press. Forging can produce strong and durable components with excellent mechanical properties. C86500 bronze is highly forgeable, and its high strength makes it an excellent material for forging components that require high strength and durability.

Extrusion: It involves pushing the material through a die to produce a uniform shape. Extrusion is often used to produce rods, tubes, and other shapes that require high precision and consistency. C86500 bronze is highly extrudable, and its high strength and wear resistance make it an ideal material for producing components that require high precision and consistency.

In addition to these common fabrication processes, C86500 bronze can also be machined, welded, and soldered. Machining is a process used to shape and finish the material, while welding and soldering are used to join different components together. C86500 bronze is highly machinable, weldable, and solderable, which makes it a versatile material that can be customized to meet specific manufacturing needs.

In summary, C86500 bronze is a versatile material that can be fabricated using several common processes, including casting, forging, and extrusion. These processes can produce components with excellent mechanical properties, high precision, and consistency. C86500 bronze can also be machined, welded, and soldered, which makes it a highly customizable material that can meet the specific needs of various applications.

Chemical Composition

C86500 is a type of high-strength manganese bronze that is widely used in various industrial applications for its excellent mechanical and corrosion-resistant properties. Understanding the chemical composition of C86500 is essential for selecting the right material for specific applications. Here is a breakdown of the chemical composition of C86500:

| Element | Composition (%) |

|---|---|

| Copper (Cu) | 60.00 – 68.00 |

| Manganese (Mn) | 22.00 – 26.00 |

| Aluminum (Al) | 5.50 – 7.50 |

| Iron (Fe) | 2.00 – 4.00 |

| Zinc (Zn) | Max 1.00 |

| Nickel (Ni) | Max 1.00 |

| Lead (Pb) | Max 0.20 |

| Tin (Sn) | Max 0.20 |

| Phosphorus (P) | Max 0.15 |

| Silicon (Si) | Max 0.10 |

| Sulfur (S) | Max 0.08 |

| Antimony (Sb) | Max 0.05 |

| Arsenic (As) | Max 0.05 |

| Bismuth (Bi) | Max 0.03 |

As seen from the table, C86500 is predominantly made up of copper and manganese, with the addition of aluminum, iron, and small amounts of other elements to enhance its properties. Copper provides the material with its excellent thermal and electrical conductivity, while manganese improves its strength and corrosion resistance.

Aluminum is added to improve the material’s hardness and wear resistance, while iron enhances its strength and toughness. Zinc, nickel, lead, and tin are added in small amounts to improve the material’s machinability and castability. Phosphorus is added to improve the material’s fluidity during casting, while sulfur and antimony are added to improve its machinability. Arsenic and bismuth are added in trace amounts to improve the material’s casting properties.

In conclusion, the chemical composition of C86500 plays a critical role in determining its properties and suitability for specific applications. The addition of specific elements enhances the material’s mechanical, thermal, and electrical properties, making it a highly versatile and reliable material for various industrial applications.

Physical Properties of “C86500”

C86500 is a high-strength manganese bronze alloy with excellent physical properties that make it suitable for a wide range of applications. Here are some of the key physical properties of C86500:

Density: The density of C86500 is 7.62 g/cm3 (0.276 lb/in3), which is relatively high compared to other copper alloys. This property makes C86500 a dense and heavy material, which can be beneficial in certain applications where weight and density are desirable.

Melting point: C86500 has a relatively high melting point of around 1030°C (1886°F), which is typical of most copper alloys. This property makes C86500 suitable for high-temperature applications where the material is exposed to extreme heat or thermal stress.

Thermal conductivity: C86500 has a high thermal conductivity of 43.9 W/mK (255 BTU-in/hr-ft2-°F), which means that it can transfer heat quickly and efficiently. This property makes C86500 suitable for use in heat exchangers, radiator components, and other applications where heat transfer is critical.

Electrical conductivity: C86500 has an excellent electrical conductivity of 23.9 MS/m (74.2% IACS), which makes it an ideal material for use in electrical applications. This property allows C86500 to conduct electricity efficiently, which is important for applications such as electrical contacts and connectors.

Magnetic properties: C86500 is a non-magnetic material, which means that it does not exhibit any magnetic properties. This property makes it suitable for applications where magnetic interference is a concern.

In summary, the physical properties of C86500 make it a versatile material that can be used in various applications. Its high density, melting point, thermal conductivity, and electrical conductivity make it suitable for use in heat transfer and electrical applications. Its non-magnetic properties also make it an ideal material for applications where magnetic interference is a concern.

Fabrication Properties

C86500 is a type of high-strength manganese bronze alloy that has excellent fabrication properties, making it a popular choice in various industrial applications. Here are some of the key fabrication properties of C86500:

Machinability: C86500 has good machinability, making it easy to cut, drill, and shape. This property makes it an ideal material for applications that require intricate parts and components.

Weldability: C86500 is generally considered to be weldable using various welding techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. However, preheating and post-weld heat treatment may be necessary to prevent cracking and ensure good weld quality.

Formability: C86500 can be easily formed using various processes, including cold working, hot working, and forging. However, due to its high strength and hardness, it may require higher forming pressures and temperatures compared to other materials.

Casting: C86500 is an excellent material for casting due to its good fluidity and excellent castability. It can be cast using various casting processes, including sand casting, investment casting, and continuous casting.

Surface finish: C86500 has excellent surface finish properties, allowing it to achieve a high-quality surface finish after various machining and surface treatment processes. This makes it an ideal choice for use in components that require a high-quality finish.

In summary, the fabrication properties of C86500 make it a versatile material with a wide range of applications. Its good machinability, weldability, formability, castability, and surface finish properties make it easy to work with and process, making it an ideal choice for use in various industrial applications.

Applicable Specifications

C86500, also known as manganese bronze, is a type of brass that contains high levels of manganese. This gives the material unique mechanical and corrosion-resistant properties that make it ideal for use in various industrial applications. To ensure its quality and reliability, C86500 is produced to meet specific industry standards and specifications. Here are some of the applicable specifications for C86500:

ASTM B22: This specification covers the requirements for C86500 manganese bronze alloy plate, sheet, strip, and rolled bar.

SAE J461: This specification covers the chemical composition and mechanical properties of manganese bronze alloys, including C86500.

SAE J462: This specification establishes the requirements for manganese bronze alloy ingots and castings produced by various casting methods.

MIL-B-24480: This specification covers the requirements for manganese bronze alloy castings for use in seawater system piping and valve components.

QQ-C-390: This specification covers the requirements for C86500 manganese bronze alloy castings for use in marine and other heavy-duty applications.

In addition to these specifications, C86500 may also be subject to other industry standards and regulations depending on the specific application and use case.

By following these specifications, manufacturers can ensure that C86500 materials meet the necessary requirements for their intended use, including mechanical properties, corrosion resistance, and overall durability. Whether you are looking for a material for use in marine equipment, industrial machinery, or other heavy-duty applications, C86500 is an excellent choice that is sure to deliver exceptional performance and reliability.

Thermal Properties

C86500, also known as high-silicon bronze, is a popular material choice for high-stress and high-temperature applications due to its excellent thermal properties. Here are some of the key thermal properties of C86500:

Thermal conductivity: C86500 has a high thermal conductivity, which makes it an ideal material for applications that require efficient heat transfer. This property also makes it a good choice for use in heat exchangers, radiators, and other applications that involve heat dissipation.

Thermal expansion: C86500 has a low coefficient of thermal expansion, which means that it expands very little when heated. This property makes it an ideal material for use in applications that require dimensional stability at high temperatures.

Melting point: C86500 has a relatively high melting point, making it suitable for high-temperature applications. Its melting point is around 1,932°F (1,055°C), which is higher than that of many other copper alloys.

In addition to its thermal properties, C86500 also has excellent corrosion resistance, making it an ideal material for use in harsh environments. Its high strength, durability, and machinability also make it a popular choice for a wide range of applications in various industries.

In conclusion, C86500 is a versatile material with excellent thermal properties that make it ideal for use in high-stress and high-temperature applications. Its high thermal conductivity, low coefficient of thermal expansion, and high melting point make it a reliable choice for applications that require efficient heat transfer, dimensional stability, and resistance to high temperatures.

Typical Uses

C86500 is a type of high-strength manganese bronze that has excellent mechanical and corrosion-resistant properties. This material is widely used in various industries for its unique combination of properties that make it ideal for a range of applications. Here are some of the typical uses of C86500:

- Marine applications: Due to its excellent corrosion-resistant properties, C86500 is commonly used in marine applications such as shipbuilding, offshore drilling platforms, and other marine components.

- Aerospace applications: C86500 is also used in aerospace applications due to its high strength-to-weight ratio and excellent wear resistance. It is used in the manufacture of aircraft engine components, landing gear, and other critical aircraft parts.

- Industrial machinery: C86500 is also used in industrial machinery applications such as gears, bushings, and bearings due to its excellent wear and corrosion-resistant properties.

- Electrical applications: The excellent electrical conductivity of C86500 makes it an ideal material for use in electrical applications such as connectors, switches, and other electronic components.

- Automotive applications: C86500 is used in automotive applications such as drivetrain components, bushings, and bearings due to its high strength, wear resistance, and corrosion resistance.

- Construction industry: C86500 is used in the construction industry for various applications such as door handles, locks, and other decorative elements.

In summary, C86500 is a versatile material with a range of applications due to its unique combination of properties. Its excellent corrosion resistance, high strength-to-weight ratio, wear resistance, and electrical conductivity make it an ideal material for a range of industries and applications.

Equivalents

C86500, also known as High-Silicon Bronze A, is a material with excellent corrosion resistance and wear properties. While it is commonly used in marine and plumbing applications, there are several other materials that can be used as equivalents to C86500. Here are some of the most common equivalent materials:

C86200: Also known as SAE 430B bronze, C86200 is a high-strength phosphor bronze alloy with high silicon content, making it ideal for applications that require good corrosion resistance and high strength. It is commonly used in marine hardware, valves, and pumps.

C87600: This material is also known as silicon bronze and has excellent resistance to corrosion and wear. It is ideal for use in marine and plumbing applications and has good machinability, making it easy to form into various shapes.

C87500: Like C86500, C87500 is a silicon bronze material with excellent corrosion resistance and the ability to withstand harsh outdoor environments. It is commonly used in marine and architectural applications.

It is important to consider the specific needs of your project before selecting a material, as each has its own strengths and weaknesses. While C86500 is a popular material, these equivalent materials offer a range of options for various applications.

Mechnical Properties

C86500, also known as High-Silicon Bronze A, is a copper-based alloy that is known for its excellent mechanical properties. This alloy is widely used in various applications, including marine hardware, plumbing fixtures, and electrical components. Let’s take a closer look at the mechanical properties of C86500.

Tensile Strength: The tensile strength of C86500 is typically in the range of 75-85 ksi (kilopounds per square inch). This high strength makes C86500 an ideal material for applications that require good load-bearing capacity, such as marine hardware and electrical connectors.

Yield Strength: The yield strength of C86500 is typically in the range of 35-40 ksi. This is the amount of stress that a material can withstand before it begins to deform permanently. A high yield strength is desirable in applications where the material will be subjected to repeated stress, such as plumbing fixtures.

Elongation: The elongation of C86500 is typically in the range of 10-15%. This is the amount of deformation that a material can undergo before it breaks. A high elongation is desirable in applications where the material will be subjected to bending or other types of deformation, such as electrical connectors.

Hardness: The hardness of C86500 is typically in the range of 80-90 Brinell. This is a measure of the material’s resistance to indentation. A high hardness is desirable in applications where the material will be subjected to wear or abrasion, such as marine hardware.

In summary, C86500 has excellent mechanical properties that make it an ideal material for a wide range of applications. Its high tensile and yield strength, as well as its high elongation and hardness, make it suitable for use in marine hardware, plumbing fixtures, and electrical components.