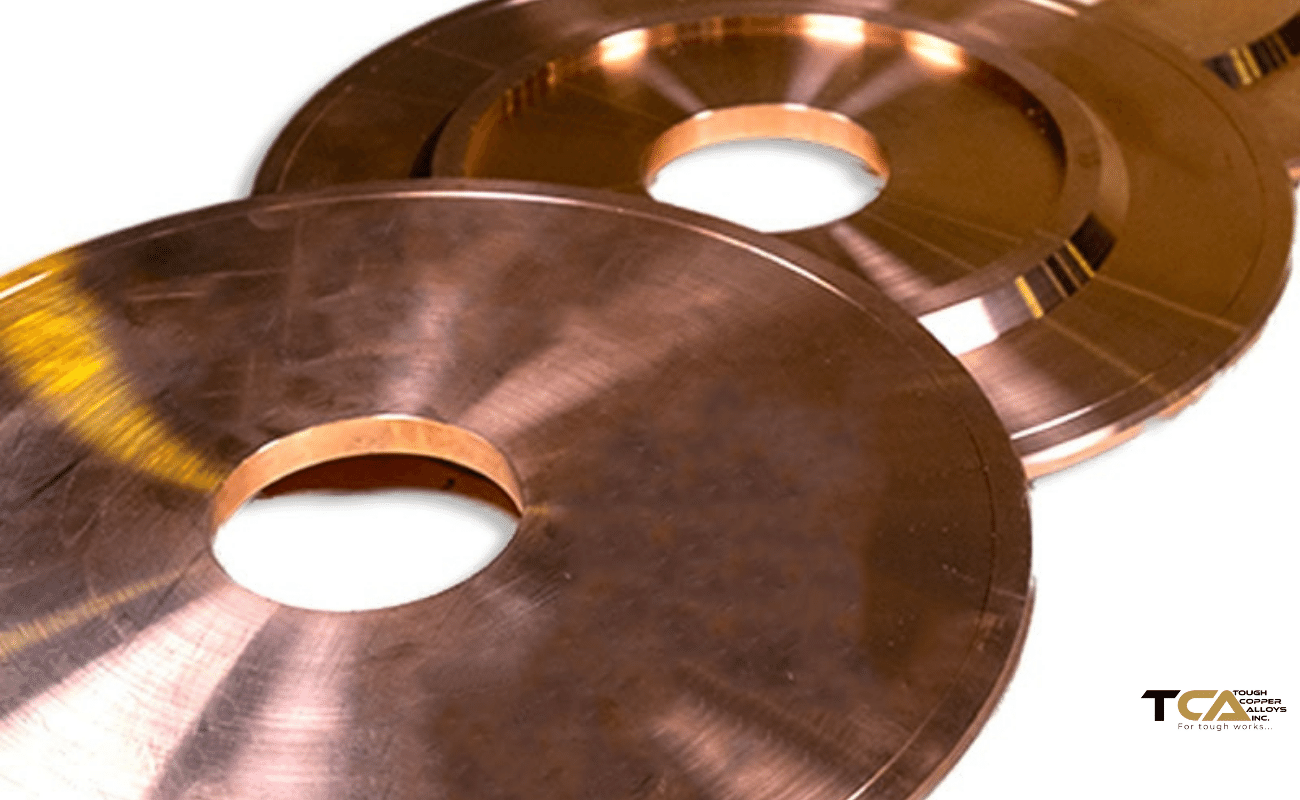

What is “C70250” Material?

C70250, also known as silicon bronze alloy C65500, is a high-strength copper alloy with excellent corrosion resistance and thermal conductivity. It is a cost-effective alternative to brass and stainless steel and is widely used in various industries. Here’s what you need to know about C70250 material:

Chemical Composition: C70250 is a copper-based alloy that contains 3% silicon, 1% manganese, and small amounts of iron, zinc, and nickel. The addition of silicon gives this alloy its strength and corrosion resistance.

Physical Properties: C70250 has a density of 8.4 g/cm³, a melting point of 1,083°C, and a thermal conductivity of 57 W/m·K. It has a high electrical conductivity and is non-magnetic.

Fabrication Properties: Cupro NSH is a highly malleable and ductile material that can be easily formed into various shapes and sizes. It can be welded and brazed using standard methods.

Typical Uses: C70250 is used in various applications such as marine hardware, electrical components, plumbing fixtures, and architectural elements. Its excellent corrosion resistance makes it a popular choice for outdoor and marine environments.

Equivalent Materials: C70250 is also known by other trade names such as CDA 655, SAE J461, ASTM B96, and MIL-B-24480.

In conclusion, C70250 is a high-strength copper alloy with excellent corrosion resistance and thermal conductivity. Its unique properties make it a cost-effective alternative to other materials in various applications. Contact us today to learn more about Cupro NSH and how it can benefit your specific needs.

Application Areas & Industries

C70250, also known as silicon bronze alloy CDA 702, is a high-strength copper alloy that is widely used in various industries for its unique properties and versatility in fabrication. Here are some of the application areas and industries where C70250 is commonly used:

- Architecture and Construction: C70250 is used in architectural applications such as decorative trim, roofing, and gutters. Its corrosion resistance, durability, and malleability make it an ideal material for these applications.

- Marine Industry: C70250 is widely used in the marine industry for components such as propellers, shafts, and hardware. Its corrosion resistance and strength make it an ideal material for these harsh environments.

- Electrical and Electronics Industry: C70250 is an ideal material for electrical and electronics applications due to its high electrical conductivity and resistance to corrosion. It is used in connectors, switches, and other components that require high electrical conductivity.

- Automotive Industry: C70250 is used in the automotive industry for various components such as bushings and bearings. Its high strength and wear resistance make it an ideal material for these applications.

- Aerospace and Defense Industry: C70250 is used in the aerospace and defense industry for various applications such as bearings, gears, and bushings. Its strength and corrosion resistance make it an ideal material for these applications.

In conclusion, C70250 is a versatile copper alloy that is widely used in various industries for its unique properties such as high strength, corrosion resistance, and conductivity. Its application areas and industries range from architecture and construction to the marine industry, making it a popular material for a wide range of applications. Contact us today to learn more about C70250 and how it can benefit your specific needs.

Common Fabrication Processes of “C70250”

C70250, also known as Berylco 25, is a copper-nickel-beryllium alloy that offers excellent strength, corrosion resistance, and electrical conductivity. Its unique properties make it an ideal choice for various industries, including aerospace, electronics, and telecommunications. Here are some of the common fabrication processes used for C70250:

- Machining: C70250 can be easily machined using standard machining techniques such as drilling, milling, and turning. Due to its high strength, the use of high-speed steel tools is recommended.

- Welding: C70250 can be welded using gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. However, special care should be taken due to the release of toxic beryllium fumes during welding.

- Forming: Cupro NSH can be easily formed into various shapes using standard forming techniques such as bending, stamping, and drawing. However, due to its high strength, special tools and equipment may be required.

- Heat treatment: C70250 can be heat treated to increase its strength and hardness. The recommended heat treatment process is solution annealing followed by aging.

In conclusion, C70250 is a versatile copper-nickel-beryllium alloy that offers excellent properties and can be easily fabricated using standard techniques such as machining, welding, forming, and heat treatment. Its unique properties make it an ideal material for various applications in industries such as aerospace, electronics, and telecommunications. Contact us today to learn more about C70250 and how it can benefit your specific needs.

Chemical Composition

C70250 is a copper-nickel-silicon alloy that is known for its excellent resistance to corrosion and erosion in seawater and other marine environments. The chemical composition of C70250 includes high levels of copper, nickel, and silicon, along with smaller amounts of iron, manganese, and zinc. Here is a table outlining the chemical composition of C70250:

| Element | Composition (%) |

|---|---|

| Copper | 83.5 – 86.5 |

| Nickel | 4.0 – 5.5 |

| Silicon | 4.0 – 5.5 |

| Iron | 2.0 – 3.0 |

| Manganese | 1.5 – 2.5 |

| Zinc | 1.5 – 2.5 |

The high copper content gives C70250 good electrical conductivity, while the nickel and silicon content provide its excellent resistance to corrosion and erosion. Iron, manganese, and zinc are added as impurities, but they do not significantly affect the alloy’s properties. The precise composition of C70250 may vary depending on the manufacturer and the specific application. Contact us today to learn more about C70250 and its chemical composition.

Physical Properties

C70250 is a copper-nickel-tin alloy with excellent strength and wear resistance, making it suitable for a variety of applications. Here are some of the physical properties of C70250:

Density: 8.83 g/cm3

Melting Point: 1065 °C (1950 °F)

Thermal Conductivity: 42.9 W/mK

Electrical Conductivity: 6.5% IACS

Modulus of Elasticity: 117 GPa (17,000 ksi)

Coefficient of Thermal Expansion: 17.4 µm/m-°C (20-300 °C)

Cupro NSH has a high density and melting point, making it suitable for use in high-temperature environments. Its high thermal conductivity and electrical conductivity also make it an ideal choice for applications that require excellent heat and electrical conductivity.

The modulus of elasticity of C70250 is higher than that of many other copper alloys, making it suitable for applications that require high strength and stiffness. Additionally, its coefficient of thermal expansion is relatively low, which means that it is less likely to expand or contract significantly in response to temperature changes.

In summary, C70250 is a copper-nickel-tin alloy with excellent physical properties, including high density, melting point, thermal and electrical conductivity, and modulus of elasticity. These properties make it suitable for a wide range of applications, including electrical and mechanical components, marine applications, and high-temperature environments. Contact us today to learn more about C70250 and how it can benefit your specific needs.

Fabrication Properties of “C70250”

C70250, also known as silicon bronze, is a copper alloy that is easy to fabricate due to its excellent workability and hot formability. It can be easily shaped into various forms using processes such as casting, forging, and extrusion. Here are some of the key fabrication properties of C70250:

Machinability: C70250 has good machinability properties due to its relatively low hardness and excellent chip-forming ability. It can be easily machined using conventional techniques such as turning, drilling, and milling.

Formability: Cupro NSH has excellent formability properties due to its low melting point and good ductility. It can be formed into various shapes using processes such as bending, stamping, and deep drawing.

Weldability: C70250 has good weldability properties due to its low melting point and good thermal conductivity. It can be easily welded using various techniques such as gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW).

Corrosion resistance: C70250 has excellent corrosion resistance properties due to the presence of silicon in its composition. It is resistant to corrosion from seawater, brine solutions, and some acids.

In conclusion, C70250 is an excellent material for fabrication due to its excellent workability, formability, and weldability properties. It can be easily shaped and formed into various shapes using processes such as casting, forging, and extrusion. Its fabrication properties make it a popular choice in various industries such as architecture, marine, and automotive. Contact us today to learn more about C70250 and how it can benefit your specific needs.

Applicable Specifications

C70250 is a copper-nickel-silicon alloy that has excellent resistance to corrosion, particularly in seawater applications. To ensure the quality and reliability of this material, it must meet specific standards and specifications. Some of the applicable specifications for C70250 include:

ASTM B151: This specification covers copper-nickel-silicon alloys in the form of plate, sheet, strip, and rolled bar. C70250 is one of the alloys covered by this specification.

ASTM B466: This specification covers seamless copper-nickel pipes and tubes. C70250 is one of the alloys that may be used to manufacture pipes and tubes under this specification.

ASTM B467: This specification covers welded copper-nickel pipes. C70250 is one of the alloys that may be used to manufacture pipes under this specification.

MIL-T-16420K: This military specification covers copper-nickel-silicon alloy rods, bars, and forgings. C70250 is one of the alloys covered by this specification.

In addition to these specifications, Cupro NSH may also be required to meet customer-specific requirements or industry standards. It is important to ensure that the material meets all applicable specifications to ensure its performance and reliability in your application.

In summary, C70250 is a copper-nickel-silicon alloy that has excellent corrosion resistance in seawater applications. To ensure its quality and reliability, it must meet specific standards and specifications such as ASTM B151, ASTM B466, ASTM B467, and MIL-T-16420K. Contact us today to learn more about the applicable specifications for C70250 and how it can benefit your specific needs.

Thermal Features of Cupro NSH

C70250 is a copper-nickel-silicon alloy with excellent thermal properties that make it suitable for various applications where high thermal conductivity is required. The following are some of the key thermal properties of C70250:

- Thermal Conductivity: Cupro NSH has a thermal conductivity of 36.7 W/mK at 20°C, which is higher than that of pure copper. This property makes it a good choice for heat exchangers, cooling systems, and other applications where efficient heat transfer is essential.

- Coefficient of Thermal Expansion: C70250 has a relatively low coefficient of thermal expansion of 16.5 µm/m°C at 20°C, which means it does not expand or contract much with temperature changes. This property makes it ideal for use in precision instruments, such as clocks and watches.

- Melting Point: C70250 has a melting point of around 1083°C, which is slightly lower than that of pure copper. This property makes it easy to melt and cast into various shapes and sizes.

- Specific Heat Capacity: C70250 has a specific heat capacity of 0.385 J/g°C at 20°C, which is higher than that of most copper alloys. This property makes it suitable for use in applications where high heat capacity is required, such as in heat sinks.

In summary, Cupro NSH is a copper-nickel-silicon alloy with excellent thermal properties, including high thermal conductivity, low coefficient of thermal expansion, relatively low melting point, and high specific heat capacity. These properties make it suitable for a wide range of applications where efficient heat transfer and management are essential.

Typical Uses of “C70250”

C70250 is a copper-nickel-silicon alloy that offers excellent corrosion resistance, high strength, and good electrical conductivity. It is commonly used in various industrial applications that require these properties. Here are some of the typical uses of C70250:

- Marine applications: C70250’s high resistance to seawater corrosion makes it ideal for marine applications such as shipbuilding, offshore oil rigs, and desalination plants.

- Electrical and electronic components: C70250’s good electrical conductivity makes it suitable for use in electrical and electronic components such as connectors, switches, and circuit breakers.

- Aerospace industry: Cupro NSH’s high strength and corrosion resistance make it a popular choice for aerospace applications such as aircraft components and parts.

- Chemical processing: C70250’s corrosion resistance and high strength make it suitable for use in chemical processing equipment such as heat exchangers, valves, and pumps.

- Automotive industry: Cupro NSH’s excellent resistance to wear and corrosion make it an ideal material for use in automotive parts such as brake systems, fuel lines, and radiators.

In addition to these applications, C70250 may also be used in other industries such as construction, telecommunications, and medical equipment. Its unique combination of properties makes it a versatile material for various applications. Contact us today to learn more about C70250 and how it can benefit your specific needs.

Equivalents

C70250 is a copper alloy that is known for its exceptional strength, durability, and resistance to wear and tear. While it is a popular choice in many industries, there may be instances where an equivalent material is needed due to availability, cost, or specific performance requirements. Here are some alternatives to consider:

C51000: Also known as phosphor bronze 5%, this high-strength copper alloy has excellent resistance to corrosion, wear, and fatigue. It is often used in applications that require high-stress resistance, such as springs, fasteners, and electrical connectors.

C54400: Also known as phosphor bronze B, this copper alloy has similar properties to C70250, including high strength and corrosion resistance. It is commonly used in marine and industrial applications that require resistance to saltwater corrosion.

When choosing a copper alloy, it is important to consider your specific requirements such as strength, conductivity, corrosion resistance, and more. By doing so, you can choose the right material for your needs. While C70250 is a popular choice, it may not always be the best option for your application. Contact us today to learn more about these alternatives and find the perfect material for your application.