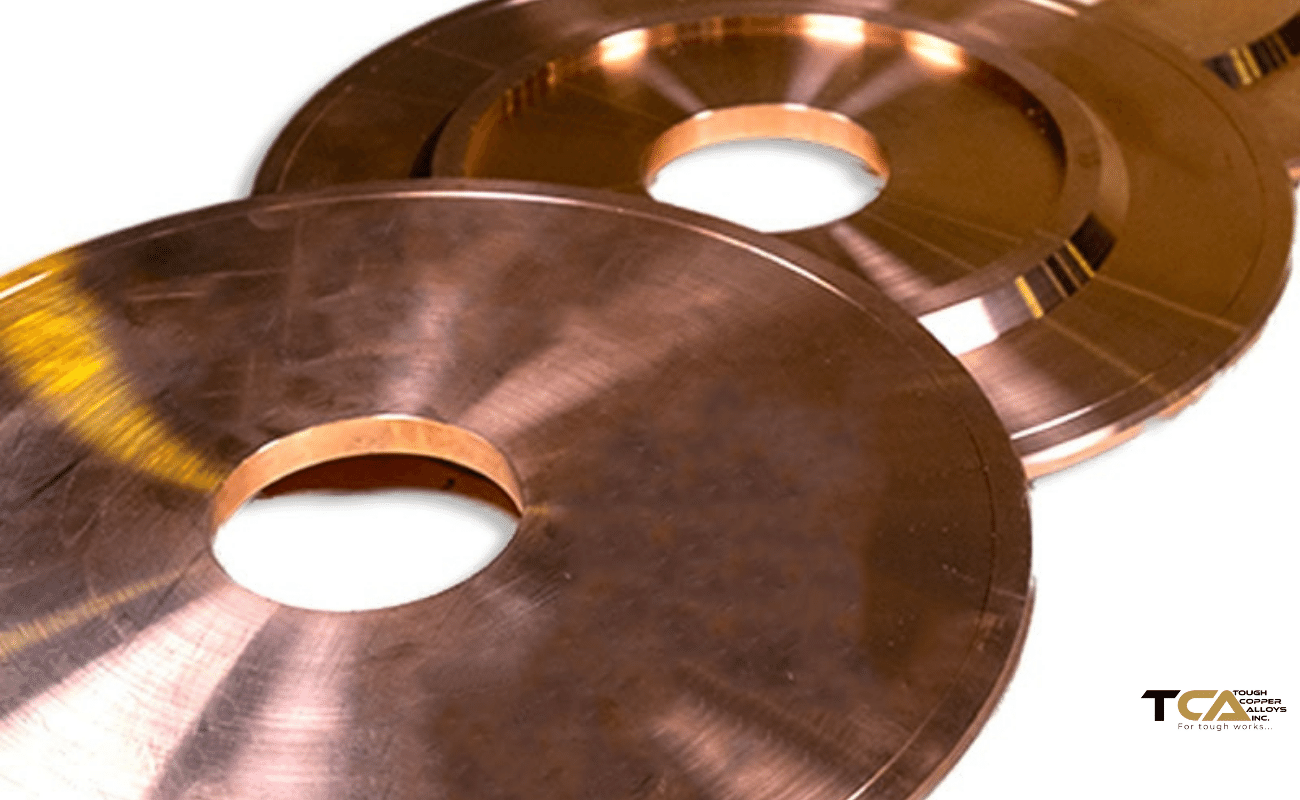

What is “C18000” Material?

C18000 is a high-performance copper chromium nickel silicon alloy that offers excellent thermal and electrical conductivity, as well as exceptional strength and hardness. This material is widely used in various industries, including automotive, aerospace, electronics, and telecommunications, where its unique combination of properties makes it an ideal choice for a range of applications.

One of the key advantages of C18000 is its high thermal conductivity, which makes it an excellent choice for heat sinks and other thermal management applications. Its exceptional electrical conductivity also makes it ideal for use in electrical contacts and other high-current applications.

In addition to its electrical and thermal properties, Cupro NSS also offers excellent strength and hardness, making it a popular choice for high-stress applications such as bearings, valve seats, and gears. It also has good resistance to corrosion, making it a suitable material for use in harsh environments.

When working with C18000, it’s important to understand its key fabrication properties. It can be readily welded, brazed, and soldered using standard techniques, and can also be machined using conventional machining methods. However, due to its high hardness and strength, it may require specialized tooling and machining techniques.

In conclusion, C18000 is a versatile and high-performance material that offers a unique combination of properties suitable for a wide range of applications across various industries. If you’re interested in using C18000 for your project, contact us today to learn more about its properties and how it can benefit your application.

Fabrication Areas & Industries

C18000, also known as chromium copper, is a versatile copper alloy with excellent thermal and electrical conductivity, high strength, and resistance to corrosion and wear. Its unique properties make it ideal for various fabrication areas and industries. Here are some of the areas and industries where C18000 is commonly used:

Electrical and Electronics Industry: C18000 is commonly used in the electrical and electronics industry due to its excellent thermal and electrical conductivity. It is used in components such as heat sinks, switch gears, and connectors.

Automotive Industry: C18000 is used in the automotive industry for various components such as contacts, springs, and conductors. Its high electrical conductivity, thermal conductivity, and strength make it an ideal material for these applications.

Aerospace and Defense Industry: Cupro NSS is used in the aerospace and defense industry for various components such as landing gear parts, engine components, and electrical connectors. Its high strength, excellent wear resistance, and corrosion resistance make it an ideal material for these applications.

Plastic Molding Industry: C18000 is used in the plastic molding industry for its excellent thermal conductivity, which helps in cooling the molds more efficiently. It is also used in mold components that require high strength and wear resistance.

Jewelry Industry: Cupro NSS is sometimes used in the jewelry industry due to its high polishability and resistance to tarnishing.

In conclusion, C18000 is a versatile copper alloy that finds its use in various fabrication areas and industries. Its unique properties such as high electrical conductivity, thermal conductivity, strength, and corrosion resistance make it an ideal material for a wide range of applications. Contact us today to learn more about C18000 and how it can benefit your specific needs.

Common Fabrication Processes of “C18000”

C18000, also known as chromium copper, is a versatile copper alloy that is widely used in various industries for its unique properties. It can be easily fabricated using a range of common processes, making it a popular material for many applications. Here are some of the common fabrication processes used for C18000:

- Machining: C18000 can be easily machined using conventional techniques such as turning, milling, drilling, and tapping. Due to its high strength and hardness, carbide tooling is recommended for machining operations.

- Welding: Cupro NSS can be welded using various techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. Preheating may be required to prevent cracking, and post-weld heat treatment may be necessary to restore the material’s properties.

- Brazing: C18000 can be brazed using various methods such as torch brazing, furnace brazing, and induction brazing. The use of a proper flux is recommended to prevent oxidation and ensure a strong bond.

- Forming: Cupro NSS can be formed into various shapes using techniques such as bending, punching, and deep drawing. Due to its high strength and hardness, specialized tooling may be required for certain forming operations.

- Heat Treatment: C18000 can be heat-treated to improve its mechanical properties such as strength and hardness. Common heat treatment processes include solution annealing, quenching, and tempering.

In conclusion, C18000 is a versatile copper alloy that can be easily fabricated using common processes such as machining, welding, brazing, forming, and heat treatment. Its ease of fabrication and unique properties make it a popular material for various applications in industries such as aerospace, automotive, and electronics. Contact us today to learn more about C18000 and how it can benefit your specific needs.

Chemical Composition

C18000, also known as Copper Chromium Nickel Silicon, is a copper alloy with excellent strength, ductility, and corrosion resistance. The chemical composition of C18000 includes copper as the primary component, along with small amounts of chromium, nickel, and silicon. The table below shows the chemical composition of C18000:

| Element | Composition (%) |

|---|---|

| Copper | 95.0 – 97.5 |

| Chromium | 0.1 – 1.0 |

| Nickel | 0.5 – 1.5 |

| Silicon | 0.05 – 0.25 |

| Others | Max 0.5 |

The high copper content of C18000 provides excellent electrical and thermal conductivity, while the addition of chromium, nickel, and silicon enhances its strength and corrosion resistance. This combination of properties makes C18000 an ideal material for various applications in the electrical, automotive, aerospace, and medical industries.

In conclusion, the chemical composition of C18000 includes copper as the primary component, along with small amounts of chromium, nickel, and silicon. This alloy’s unique composition provides it with excellent strength, ductility, and corrosion resistance, making it a popular choice for many applications. Contact us today to learn more about C18000 and how it can benefit your specific needs.

Physical Properties of “C18000”

C18000, also known as copper chromium nickel silicon, is a high-strength copper alloy with excellent corrosion resistance and good electrical conductivity. Its physical properties make it a popular choice for a variety of applications. Here are some of the physical properties of C18000:

Density: The density of C18000 is 8.8 g/cm³, making it a relatively lightweight material.

Melting Point: Cupro NSS has a melting point of 1080-1130°C, which allows it to withstand high temperatures without losing its strength.

Thermal Conductivity: C18000 has a thermal conductivity of 170 W/m·K, which makes it an ideal material for heat exchangers and other applications that require efficient heat transfer.

Electrical Conductivity: C18000 has an electrical conductivity of 25% IACS, which is lower than some other copper alloys, but still sufficient for many electrical applications.

Magnetic Properties: Cupro NSS is non-magnetic, which makes it suitable for applications where magnetism is undesirable.

In conclusion, C18000 is a high-strength copper alloy with excellent corrosion resistance and good electrical conductivity. Its physical properties, including its lightweight nature, high melting point, thermal conductivity, and non-magnetic properties, make it a versatile material for various applications. Contact us today to learn more about how C18000 can benefit your specific needs.

Fabrication Properties

C18000 is a high-strength copper alloy that is commonly used in various industries due to its excellent fabrication properties. Here are some of the key fabrication properties of C18000:

Machinability: C18000 is known for its excellent machinability, which allows it to be easily machined into complex shapes and components. This makes it an ideal material for applications that require intricate designs.

Weldability: C18000 has good weldability, which allows it to be easily welded using a variety of welding techniques. This makes it an ideal material for applications that require joining multiple components together.

Formability: Cupro NSS has good formability, which allows it to be easily formed into various shapes and sizes. This makes it an ideal material for applications that require complex shapes and designs.

Heat treatment: C18000 can be heat treated to improve its mechanical properties. Heat treatment can increase its strength and hardness, making it an ideal material for applications that require high strength and wear resistance.

In conclusion, C18000 is a versatile copper alloy with excellent fabrication properties such as machinability, weldability, formability, and heat treatability. Its unique properties make it an ideal material for a wide range of applications in various industries. Contact us today to learn more about C18000 and how it can benefit your specific needs.

Applicable Specifications

C18000 is a high-strength copper alloy that is commonly used in various industrial applications. To ensure the quality and consistency of this material, there are specific standards and specifications that it must meet. Here are some of the applicable specifications for C18000:

ASTM B103: This specification covers phosphor bronze plate, sheet, strip, and rolled bar. It includes Cupro NSS as one of the phosphor bronze alloys covered in this specification.

SAE J461: This standard covers the chemical composition and mechanical properties of wrought and cast copper alloys. C18000 is included in the phosphor bronze alloys covered by this standard.

SAE J463: This standard covers the recommended practice for heat treatment of copper and copper alloys, including C18000.

MIL-B-5687C: This military specification covers the requirements for phosphor bronze spring wire. C18000 is included in the phosphor bronze alloys covered by this specification.

In addition to these specifications, C18000 may also be required to meet customer-specific requirements or industry standards. It is important to ensure that the material meets all applicable specifications to ensure its performance and reliability in your application.

In conclusion, C18000 is a high-strength copper alloy that is commonly used in various industrial applications. It must meet specific standards and specifications such as ASTM B103, SAE J461, SAE J463, and MIL-B-5687C to ensure its quality and consistency. Contact us today to learn more about the applicable specifications for C18000 and how it can benefit your specific needs.

Thermal Properties of “C18000”

C18000, also known as chromium copper, is a copper alloy that offers excellent thermal properties. It has a high thermal conductivity and a low coefficient of thermal expansion, making it a popular material in industries where thermal management is important. Here are some of the thermal properties of C18000:

Thermal Conductivity: C18000 has a high thermal conductivity, which means it is an excellent conductor of heat. Its thermal conductivity is about 300 W/(m·K) at room temperature, which is higher than that of many other copper alloys.

Coefficient of Thermal Expansion: Cupro NSS has a low coefficient of thermal expansion, which means it does not expand or contract significantly with changes in temperature. Its coefficient of thermal expansion is about 17.8 x 10^-6/K at room temperature.

Melting Point: C18000 has a high melting point of about 1080°C, which makes it a suitable material for high-temperature applications.

Thermal Stability: C18000 has excellent thermal stability, which means it can maintain its properties even at high temperatures. This makes it a suitable material for applications such as heat exchangers, where it is subjected to high temperatures for extended periods.

In conclusion, C18000 offers excellent thermal properties, including high thermal conductivity, low coefficient of thermal expansion, high melting point, and thermal stability. These properties make it a suitable material for a wide range of applications where thermal management is critical. Contact us today to learn more about C18000 and how it can benefit your specific needs.

Typical Uses

C18000, also known as Copper Chromium Nickel Silicon, is a high-performance copper alloy that offers excellent strength, corrosion resistance, and electrical conductivity. Its unique combination of properties makes it a popular choice in various industries. Here are some typical uses of C18000:

Electrical and Electronics Industry: Cupro NSS is an ideal material for electrical and electronics applications due to its high electrical conductivity and resistance to corrosion. It is commonly used in connectors, switches, and other components that require high electrical conductivity.

Aerospace Industry: Cupro NSS is used in the aerospace industry for various components such as bearings, bushings, and gears. Its high strength and excellent wear resistance make it an ideal material for these applications.

Automotive Industry: C18000 is used in the automotive industry for various components such as engine components, bearings, and springs. Its high strength and excellent corrosion resistance make it a popular choice for these applications.

Oil and Gas Industry: Cupro NSS is used in the oil and gas industry for various applications such as valve stems, pump shafts, and drilling equipment. Its high strength and corrosion resistance make it an ideal material for these harsh environments.

Medical Industry: C18000 is used in the medical industry for various surgical instruments and implants due to its excellent biocompatibility, high strength, and resistance to corrosion.

In conclusion, C18000 is a versatile copper alloy that is widely used in various industries for its unique properties such as high strength, excellent conductivity, and corrosion resistance. Its typical uses range from electrical and electronics to aerospace, automotive, and medical applications, making it a popular material for a wide range of applications. Contact us today to learn more about C18000 and how it can benefit your specific needs.

Equivalents

C18000 is a popular copper alloy with unique properties such as high strength, excellent conductivity, and corrosion resistance. While C18000 is a versatile material, there are also equivalents available that may better suit your specific needs. Here are some alternatives to consider:

C18200: This copper alloy is similar to C18000 in terms of its high strength, excellent conductivity, and corrosion resistance. However, it also offers improved wear resistance and is often used in applications such as bearings and bushings.

C17510: This beryllium copper alloy is known for its high strength and excellent conductivity. It is often used in applications such as electrical connectors, springs, and fasteners.

C17200: This copper alloy is known for its high electrical and thermal conductivity, making it ideal for applications such as electrical contacts, heat exchangers, and springs.

C18150: This copper alloy offers high electrical and thermal conductivity and is often used in applications such as welding electrodes, resistance welding electrodes, and heat sinks.

When selecting a copper alloy, it’s important to consider your specific requirements such as strength, conductivity, corrosion resistance, and more. By doing so, you can choose the right material for your needs. While C18000 is a popular choice, it may not always be the best option for your application. Contact us today to learn more about these alternatives and find the perfect material for your application.