What is “C72900” Material?

C72900, also known as 72900 brass or aluminum bronze, is a type of alloy that is composed of copper, aluminum, iron, and nickel. It is a high-strength, corrosion-resistant material that has many applications across a variety of industries.

One of the most notable features of C72900 is its excellent resistance to corrosion. This makes it a popular choice for applications where it will be exposed to harsh environments, such as marine hardware, valves, pumps, and heat exchangers. The material is highly resistant to pitting, crevice corrosion, and stress corrosion cracking, making it an ideal choice for seawater applications.

In addition to its excellent corrosion resistance, C72900 is also known for its high strength and durability. It has a tensile strength of 690 MPa and a high wear resistance, which makes it an excellent choice for applications where the material will be subjected to constant stress or impact. This includes aerospace, automotive, and industrial applications.

C72900 also has a high thermal conductivity, which makes it a good choice for heat exchanger applications. Its electrical conductivity is also high, which makes it suitable for electrical and electronic applications.

The physical properties of C72900 include a density of 7.78 g/cm³ and a melting point of 1025-1070°C. It is a ductile material that can be easily formed into a variety of shapes and sizes. It is also easy to machine and weld, which makes it a popular choice for manufacturing processes.

Overall, C72900 is a versatile and reliable material that offers excellent performance in a wide range of applications. Its unique combination of strength, durability, and corrosion resistance make it a popular choice in industries such as marine, aerospace, and automotive, among others. With its excellent properties and proven track record, C72900 is an ideal material for any application where strength, durability, and corrosion resistance are critical.

Application Areas & Industries

C72900, also known as 72900 brass or aluminum bronze, is a highly sought-after material that is used in a wide range of applications across different industries. Its exceptional properties, including strength, corrosion resistance, and durability, make it a versatile material choice for various applications. Here are some of the industries and application areas where C72900 finds use:

Marine Industry: The marine industry is one of the top users of C72900 due to its superior resistance to corrosion. It is commonly used for the manufacturing of marine hardware such as propeller shafts, valves, and pumps. Additionally, it is used in heat exchangers for seawater applications due to its superior resistance to corrosion.

Aerospace Industry: C72900’s high strength and durability make it an ideal material choice for components that require constant stress and impact, such as engine parts and landing gear components.

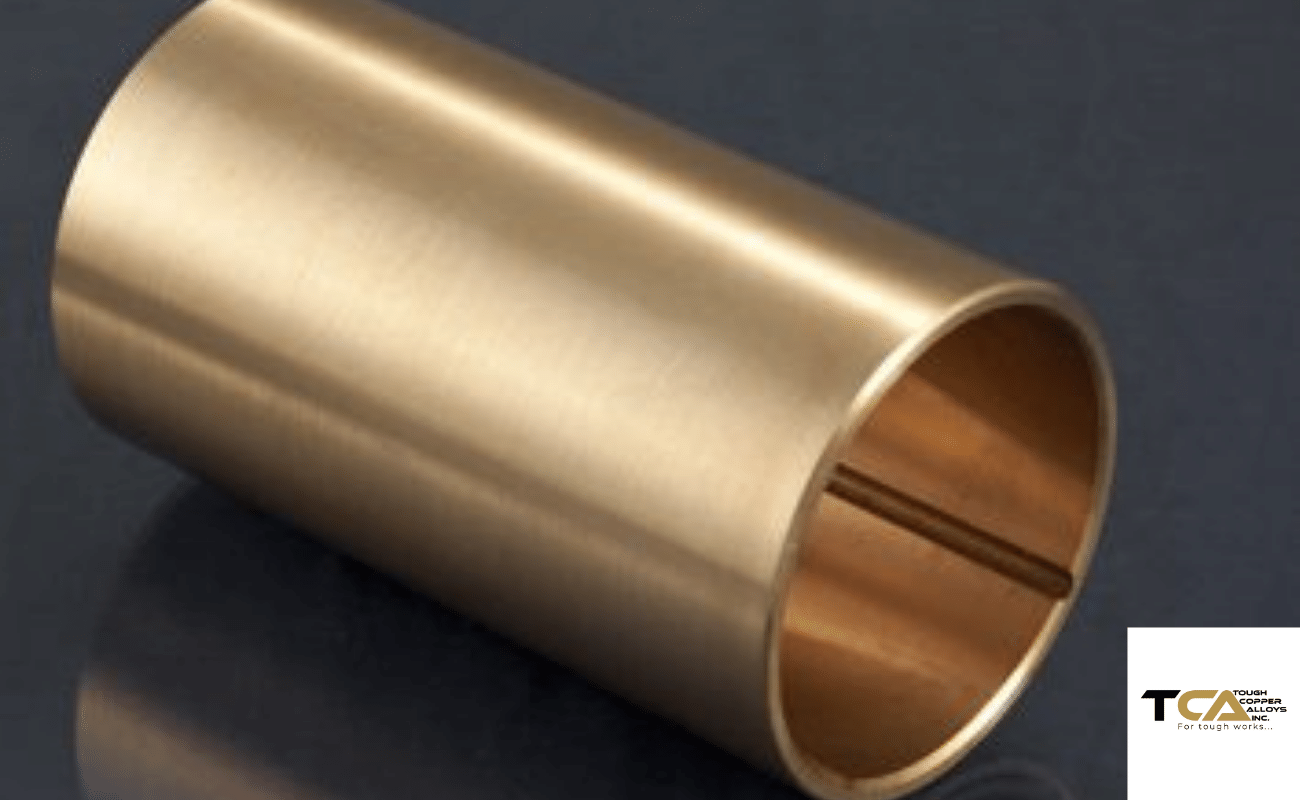

Automotive Industry: C72900 is commonly used in the automotive industry for its high strength and wear resistance, making it ideal for bearings, bushings, and other components. Its high thermal conductivity also makes it a good material choice for heat exchangers and radiators.

Industrial Machinery: C72900 is widely used in industrial machinery applications, such as gears and bearings, due to its high strength and wear resistance.

Electrical and Electronic Applications: C72900’s high electrical conductivity makes it a popular choice for electrical connectors, switches, and other components.

Construction: C72900 is sometimes used for architectural applications, such as door and window frames, due to its attractive appearance and corrosion resistance.

Mining: C72900 is used in mining equipment, such as rock drills and crushers, due to its high wear resistance.

These are just some examples of the many application areas and industries where C72900 finds use. The specific uses for C72900 may vary depending on the specific alloy composition and manufacturing process. Therefore, it’s important to consult the manufacturer or supplier for the specific properties of C72900 being used in an application.

In summary, C72900 is a versatile material that is suitable for use in many different industries and applications. Its unique combination of strength, durability, and corrosion resistance make it a popular choice for applications where performance and reliability are essential. Whether you’re in the marine, aerospace, automotive, industrial machinery, electrical, construction, or mining industry, C72900 is an excellent material choice for your application needs.

Common Fabrication Processes

C72900, also known as 72900 brass or aluminum bronze, is a popular material for various applications due to its strength, durability, and corrosion resistance. One of the reasons for its versatility is the fact that it can be fabricated using a variety of processes. Here are some common fabrication processes used for C72900:

- Casting: C72900 can be cast into complex shapes and designs using the sand casting process. This method involves creating a mold from a pattern and then pouring molten C72900 into the mold.

- Forging: Forging is a process that involves heating C72900 to a high temperature and then using pressure to shape it into the desired form. This method is often used to manufacture parts that require high strength and durability, such as gears, shafts, and valves.

- Extrusion: Extrusion is a process that involves forcing C72900 through a die to create a specific shape or profile. This process is commonly used to manufacture rods, tubes, and other long, uniform shapes.

- Machining: C72900 is an easy-to-machine material, which means it can be cut, drilled, and shaped using a variety of machine tools. Machining is often used to create precise shapes and parts for various applications.

- Welding: C72900 can be welded using a variety of welding techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. Welding is often used to join multiple pieces of C72900 together to create larger components.

- Brazing: Brazing is a process that involves heating C72900 and then bonding it to another material using a filler metal. This process is often used to create joints and connections between C72900 components and other materials.

These are just some of the most common fabrication processes used for C72900. The specific process used will depend on the specific application and the desired properties of the final product. When selecting a fabrication process for C72900, it is important to consult with a knowledgeable supplier or manufacturer to ensure that the process selected will produce the desired outcome.

Chemical Composition

C72900 is a copper-nickel-aluminum alloy that is highly valued for its excellent strength, durability, and resistance to corrosion. It is also known as 72900 brass or aluminum bronze and is used in various applications across a wide range of industries. The chemical composition of C72900 is carefully balanced to ensure optimal performance in specific applications.

Below is a table showing the chemical composition of C72900:

| Element | Composition % |

|---|---|

| Copper (Cu) | 77.0 – 79.0 |

| Nickel (Ni) | 5.5 – 6.5 |

| Aluminum (Al) | 8.5 – 9.5 |

| Iron (Fe) | 3.5 – 4.5 |

| Manganese (Mn) | 1.0 – 2.0 |

| Silicon (Si) | 0.10 – 0.20 |

| Zinc (Zn) | 0.50 max |

| Lead (Pb) | 0.05 max |

| Phosphorus (P) | 0.01 max |

Copper is the primary component of C72900, making up approximately 77-79% of the alloy’s composition. Nickel and aluminum are added to improve the alloy’s strength and corrosion resistance. Iron and manganese are included to enhance the alloy’s mechanical properties, while silicon is added to increase the alloy’s resistance to wear and corrosion. Zinc and lead are kept at low levels to avoid adverse effects on the alloy’s mechanical properties. Phosphorus is also limited to ensure the material’s good ductility and formability.

The precise chemical composition of C72900 can vary slightly depending on the specific manufacturing process and application requirements. However, the composition range given above is generally considered standard for C72900.

In conclusion, the chemical composition of C72900 plays a critical role in determining the material’s mechanical and physical properties, making it a popular choice in a wide range of industries. With its unique combination of strength, durability, and corrosion resistance, C72900 is a versatile material that can be used in many different applications.

Physical Properties

C72900, also known as 72900 brass or aluminum bronze, is a copper-based alloy that is highly sought after for its unique combination of strength, durability, and corrosion resistance. In addition to its mechanical properties, C72900 also possesses a variety of physical properties that make it an attractive material choice for a wide range of applications.

Density: C72900 has a density of 7.78 g/cm3, which is slightly higher than that of pure copper.

Melting Point: C72900 has a relatively high melting point of 1010°C (1850°F), making it suitable for use in high-temperature applications.

Thermal Conductivity: C72900 has a thermal conductivity of 50 W/m*K, which is slightly lower than that of pure copper but still considered high.

Electrical Conductivity: C72900 has excellent electrical conductivity, with a conductivity of 27% IACS (International Annealed Copper Standard).

Magnetic Properties: C72900 is not magnetic and exhibits no magnetic properties.

Corrosion Resistance: C72900 has excellent corrosion resistance, particularly in seawater and other marine environments, making it an ideal choice for marine hardware and heat exchangers.

These physical properties make C72900 an attractive material choice for a wide range of applications. Its high density and melting point make it suitable for use in high-stress, high-temperature applications, while its high thermal and electrical conductivity make it ideal for use in electrical and electronic components. Additionally, its excellent corrosion resistance makes it an ideal choice for marine and other harsh environments.

Fabrication Properties

Fabrication Properties: C72900, also known as 72900 brass or aluminum bronze, is a popular material for various industrial applications due to its excellent fabrication properties.

Machinability: One of the key fabrication properties of C72900 is its excellent machinability. It can be easily machined using standard techniques such as turning, drilling, and milling. This makes it an ideal material for fabricating complex shapes or parts that require high precision and tight tolerances.

Formability: C72900 is also easily formed using various fabrication processes, including forging, casting, and extrusion. The material can be forged into a wide range of shapes and sizes, making it ideal for various applications that require complex geometries. Additionally, C72900 can be easily cast into complex shapes using sand casting, investment casting, or die casting processes.

Weldability: Another important property of C72900 is its excellent weldability. It can be easily welded using various welding techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. This makes it easy to join C72900 parts together, which is important when fabricating large structures or components.

Heat Treatment: C72900 can be heat treated to improve its strength and other mechanical properties. The exact heat treatment process will depend on the specific alloy composition and the desired properties.

Overall, the excellent fabrication properties of C72900 make it a versatile material that is easy to fabricate using a variety of techniques. Its excellent machinability, formability, weldability, and ability to be heat treated, make it a popular material choice for fabricating complex parts, structures, and components in various industries.

Applicable Specifications

C72900 is a copper-nickel-tin alloy that is known for its exceptional strength, corrosion resistance, and machinability. This makes it a popular choice for use in various industries. To ensure that C72900 performs optimally in specific applications, it is important to select the appropriate specifications for the alloy. Here are some of the most common applicable specifications for C72900:

ASTM B171/B171M: This specification is the standard for copper-alloy plate, sheet, strip, and rolled bar in the United States, including C72900. It defines the requirements for composition, mechanical properties, and other characteristics of the alloy.

ABS: The American Bureau of Shipping has its own set of specifications for copper alloys used in marine applications, including C72900. These specifications outline the requirements for the alloy’s performance in terms of strength, corrosion resistance, and other factors.

By selecting the appropriate specifications for C72900, manufacturers and engineers can ensure that the alloy will meet the necessary requirements for their specific applications. It is important to consult the manufacturer or supplier for the specific properties and applicable specifications of C72900 before using it in any application. Additionally, when machining C72900, it is important to follow the recommended practices to avoid work hardening and ensure the best results. Overall, C72900 is a high-performance alloy that can be relied on for use in harsh environments.

Thermal Properties

C72900 is a copper-nickel-tin alloy known for its excellent thermal properties. This makes it a popular choice in various industries where heat transfer is an important consideration. Let’s take a closer look at the thermal properties of C72900.

Thermal Conductivity: C72900 has a thermal conductivity of around 50 W/m·K at room temperature. This high thermal conductivity means that heat can be transferred quickly and efficiently through the alloy, making it an ideal choice for use in heat exchangers and other applications where heat transfer is important.

Thermal Expansion: Like most metals, C72900 expands when it is heated. The coefficient of thermal expansion for C72900 is around 17.6 µm/m·K, which means that it will expand by approximately 17.6 micrometers per meter of length for every degree Celsius increase in temperature. This property is important to consider when designing components that will be exposed to changes in temperature.

Melting Point: C72900 has a relatively high melting point of around 1080°C. This means that it can withstand high temperatures without losing its mechanical or physical properties, making it an ideal choice for use in high-temperature applications.

Specific Heat Capacity: C72900 has a specific heat capacity of around 0.39 J/g·K, which means that it requires relatively little energy to change its temperature. This property is important to consider when designing heat exchangers or other components that will be exposed to changes in temperature.

In conclusion, C72900 is an alloy with excellent thermal properties that make it an ideal choice for use in various applications where heat transfer is important. Its high thermal conductivity, high melting point, and low specific heat capacity make it a reliable choice for use in high-temperature applications. If you are considering using C72900 in your next project, be sure to consult with a reputable supplier to ensure that you select the appropriate specifications for your specific application.

Typical Uses

C72900 is a copper-nickel-tin alloy that is known for its excellent mechanical properties and resistance to corrosion. This makes it a popular choice in various industries where high-performance materials are required. Here are some typical uses of C72900:

- Marine applications: C72900 is commonly used in marine environments due to its high resistance to corrosion in saltwater. It is used in components such as propeller shafts, seawater pumps, and valve stems.

- Heat exchangers: The alloy’s good thermal conductivity and resistance to corrosion make it an ideal material for heat exchangers used in various industrial applications such as power plants and chemical processing.

- Springs and fasteners: C72900’s excellent mechanical properties make it suitable for use in components such as springs, fasteners, and connectors.

- Electrical components: The alloy’s high electrical conductivity makes it a popular choice for use in electrical components such as connectors, switchgear, and circuit breakers.

- Aerospace applications: C72900’s combination of strength and corrosion resistance makes it a good choice for use in aerospace applications such as landing gear components and hydraulic tubing.

- Automotive industry: C72900’s excellent machinability and resistance to corrosion make it a popular choice in the automotive industry for use in components such as valve guides and fuel injector sleeves.

In addition to the above applications, C72900 may also be used in other industries such as construction, defense, and medical. Its unique combination of properties makes it a versatile material that can be used in various applications where high performance is required.

In conclusion, C72900 is a high-performance copper-nickel-tin alloy that is commonly used in various industries due to its excellent mechanical and thermal properties. Its typical uses range from marine applications to aerospace and automotive components, and its versatility makes it a popular choice for various other applications as well.

Equivalents

If you’re in the market for C72900, you might also be interested in knowing about some of its equivalents. C72900 is a copper-nickel-tin alloy that is well-suited for use in harsh environments due to its excellent strength and corrosion resistance. Here are a few other alloys that are similar in composition and performance to C72900:

- C70600: This alloy is also known as 90/10 copper-nickel and contains 90% copper and 10% nickel. Like C72900, it is resistant to corrosion in seawater and other harsh environments, making it a popular choice for marine applications.

- C71500: This alloy, also known as 70/30 copper-nickel, contains 70% copper and 30% nickel, as well as small amounts of iron and manganese. It is also highly resistant to corrosion and is commonly used in marine and chemical processing applications.

- C95800: This is a copper-nickel-aluminum bronze alloy that contains 78% copper, 8% aluminum, and 14% nickel. It has excellent corrosion resistance and high strength, making it a popular choice for marine hardware, pumps, and valve components.

- C63000: This is a nickel-aluminum bronze alloy that contains 81% copper, 10% aluminum, and 5% nickel. It has excellent corrosion resistance and is also known for its high strength and wear resistance, making it ideal for use in heavy-duty applications such as gears and bearings.

By considering the equivalents of C72900, you can explore a wider range of options when selecting the best material for your application. Each of these alloys has its own unique properties and specifications, so it’s important to consult with a supplier or manufacturer to determine which one is the best fit for your specific needs.

Mechanical Properties

C72900 is a copper-nickel-tin alloy that is known for its exceptional strength, corrosion resistance, and machinability. This alloy has a unique combination of properties that make it ideal for use in various industrial applications. Understanding the mechanical properties of C72900 is essential for engineers and manufacturers who want to determine its suitability for specific applications.

Here are the typical mechanical properties of C72900:

| PROPERTY | VALUE |

|---|---|

| Tensile Strength | 110 ksi |

| Yield Strength | 40 ksi |

| Elongation | 35% |

| Hardness, Rockwell | B75 |

| Modulus of Elasticity | 19,000 ksi |

As you can see from the table, C72900 has a tensile strength of 110 ksi, making it a strong and durable alloy. It also has a yield strength of 40 ksi, which means it can withstand high levels of stress without permanent deformation. The elongation of C72900 is 35%, which indicates its ability to stretch without breaking.

The hardness of C72900, as measured on the Rockwell B scale, is B75. This means it has good wear resistance and can withstand abrasion in harsh environments. Additionally, the modulus of elasticity of C72900 is 19,000 ksi, indicating its ability to return to its original shape after deformation.

C72900’s excellent mechanical properties make it ideal for use in various applications, such as marine hardware, heat exchangers, and valves. Its high strength, corrosion resistance, and machinability ensure its reliability and durability in harsh environments.

In summary, understanding the mechanical properties of C72900 is crucial in determining its suitability for specific applications. Its excellent properties make it a reliable choice for various industrial uses, and manufacturers and engineers can refer to the table above for quick reference.