What is “C97600” Material?

C97600 is a high-performance copper alloy that is widely used in various industrial applications. This material is also known as nickel silver, and it is a type of copper alloy that contains copper, nickel, and zinc in varying proportions. The composition of C97600 can vary depending on the specific application and requirements.

One of the main benefits of using C97600 material is its excellent corrosion resistance. This material is highly resistant to corrosion and tarnish, making it an ideal choice for applications where exposure to harsh environmental conditions is expected. It can withstand prolonged exposure to various corrosive elements, such as saltwater and acidic substances, without losing its mechanical properties.

In addition to its corrosion resistance, C97600 also has excellent strength and durability. This material is able to withstand high stress and is very resistant to wear and tear, making it an ideal choice for applications that require high levels of performance and reliability. Its high strength and toughness also make it resistant to deformation and cracking under high loads or impact.

Another advantage of C97600 is its excellent electrical conductivity. This material is highly conductive and is often used in electrical applications where high levels of conductivity are required. Its electrical properties make it suitable for use in a range of electrical components, such as wires, connectors, and switches.

C97600 is also known for its excellent machinability. It can be easily machined and formed into various shapes and sizes, which makes it suitable for a wide range of applications. Its ductility and malleability make it easy to work with and can be easily welded, brazed, or soldered.

Overall, C97600 is a versatile material that is well-suited for a wide range of industrial applications. Its excellent corrosion resistance, strength, durability, and electrical conductivity make it an ideal choice for many different types of projects. It is commonly used in applications such as marine hardware, musical instruments, electrical components, and decorative items. If you are looking for a high-performance material that can deliver exceptional results, C97600 is definitely worth considering.

Application Areas & Industries

C97600, also known as nickel silver, is a copper alloy that finds applications across a variety of industries due to its unique properties. In this guide, we will explore the most common application areas and industries where C97600 is used:

Manufacturing Industry: C97600’s excellent electrical conductivity and mechanical properties make it a popular choice for manufacturing electrical components like connectors, switches, and terminals. Its unique sound and resonance properties make it an ideal material for manufacturing musical instruments, such as brass instruments and guitar strings.

Marine Industry: The excellent corrosion resistance and resistance to tarnish and wear make C97600 an ideal material for marine hardware applications, including ship fittings and marine instrumentation. The alloy is also suitable for decorative marine applications such as ship ornaments and decorative plaques.

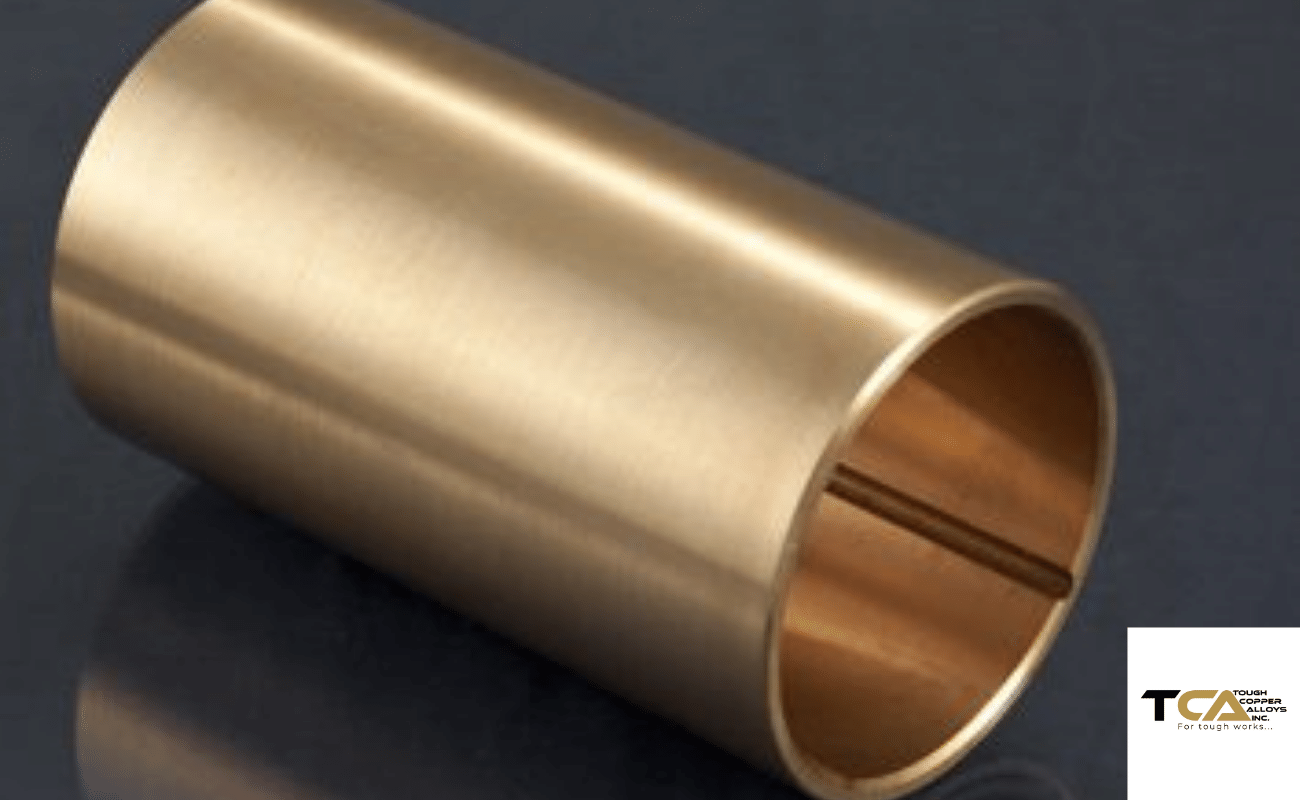

Automotive Industry: C97600’s strength, durability, wear resistance, and excellent machinability make it a popular choice for various automotive components such as bearings, bushings, and gears.

Construction Industry: C97600’s resistance to corrosion, tarnish, and wear make it a popular choice for producing decorative architectural elements like door handles, light fixtures, and railings.

Overall, C97600 is a versatile material that is used in various applications across industries. Its excellent corrosion resistance, strength, durability, and electrical conductivity make it a popular choice for different types of projects. Whether you are in the manufacturing, marine, automotive, or construction industry, C97600 is a material that is worth considering for your next project. If you’re considering using C97600 material, ensure you consult with a reliable supplier to ensure you get the right material for your specific application.

Common Fabrication Processes

C97600, also known as nickel silver, is a popular copper alloy that is widely used in various industrial applications due to its excellent properties. To make the most of its properties, C97600 is often subjected to different fabrication processes, which can modify its shape, size, and properties to meet specific application requirements. Here are some of the most common fabrication processes used for C97600:

- Casting: Casting is one of the most popular fabrication processes used for C97600. It involves melting the material and pouring it into a mold, where it solidifies and takes the shape of the mold. This process is often used to produce complex parts with intricate shapes that cannot be easily achieved through other processes.

- Forging: Forging involves heating C97600 to a high temperature and then using a hammer or press to deform it into a desired shape. This process improves the material’s strength and toughness, making it suitable for heavy-duty applications that require high durability.

- Extrusion: Extrusion involves forcing C97600 through a die to create a specific shape or profile. This process is often used to produce linear shapes, such as rods and tubes, with precise dimensions.

- Machining: Machining involves using cutting tools to remove material from a workpiece to create a specific shape. This process is often used for producing precise, small-scale parts, such as electrical connectors and terminals.

- Welding: Welding involves joining two or more pieces of C97600 by heating them to a high temperature and applying pressure. This process is often used for producing larger structures, such as marine hardware and automotive components.

- Rolling: Rolling involves passing C97600 through a series of rollers to reduce its thickness and create a desired shape. This process is often used to produce thin sheets and foils that are used in various applications, such as electrical contacts and decorative applications.

In summary, C97600 is a versatile material that can be fabricated using various processes to meet specific application requirements. The most common fabrication processes used for C97600 include casting, forging, extrusion, machining, welding, and rolling. By choosing the right fabrication process, engineers and manufacturers can create high-quality components that offer excellent strength, durability, and other properties. If you are considering using C97600 for your next project, consult with a knowledgeable supplier to ensure you are getting the right material and fabrication process for your specific application.

Chemical Composition

C97600, also known as nickel silver, is a copper alloy that contains copper, nickel, and zinc in varying proportions. The chemical composition of C97600 is crucial to its unique properties, which make it suitable for various applications across different industries.

Here is the chemical composition of C97600:

| Element | Percentage |

|---|---|

| Copper | 62-68% |

| Nickel | 10-16% |

| Zinc | 18-22% |

| Lead | 0.05% max |

| Iron | 0.25% max |

| Manganese | 0.50% max |

| Total Impurities | 0.50% max |

Copper is the primary element in C97600, accounting for 62-68% of the alloy. The addition of nickel, which makes up 10-16% of the alloy, enhances the material’s strength and corrosion resistance. Zinc, which makes up 18-22% of the alloy, enhances the material’s formability and improves its casting properties. The trace amounts of lead, iron, and manganese in the alloy serve as impurities, which should not exceed 0.05%, 0.25%, and 0.50%, respectively.

The chemical composition of C97600 is essential in determining its properties and behavior during various fabrication processes. Manufacturers and engineers must consider the chemical composition of C97600 to ensure that they select the appropriate alloy for their specific applications.

In summary, C97600 is a versatile copper alloy that contains copper, nickel, and zinc in varying proportions. Its chemical composition, as outlined in the table above, plays a crucial role in its unique properties and behavior during various fabrication processes. By understanding the chemical composition of C97600, manufacturers and engineers can ensure that they select the appropriate material for their specific applications.

Physical Properties of “C97600”

C97600, also known as nickel silver, is a copper alloy that has a unique set of physical properties. These properties make it suitable for a wide range of applications across various industries. In this guide, we will explore the physical properties of C97600 in detail:

Density: The density of C97600 is 8.94 g/cm³, which is slightly higher than pure copper. This high density makes it a good material for applications where weight is not a concern.

Melting point: C97600 has a relatively high melting point of 1100°C (2012°F). This makes it suitable for high-temperature applications where other materials might melt or deform.

Thermal conductivity: C97600 has good thermal conductivity, which makes it an excellent choice for applications that require the transfer of heat. It can effectively conduct heat, making it a popular choice for heat sinks and other thermal management applications.

Electrical conductivity: C97600 is an excellent conductor of electricity. Its electrical conductivity is even better than pure copper, which makes it a popular choice for electrical applications such as connectors, switches, and terminals.

Magnetic properties: C97600 is non-magnetic, which makes it an ideal material for applications where magnetic interference can be a problem.

Corrosion resistance: C97600 has excellent corrosion resistance. It is resistant to corrosion in both freshwater and saltwater environments, which makes it a popular choice for marine applications.

Wear resistance: C97600 has good wear resistance, which makes it an excellent choice for applications that involve sliding or rotating parts. Its wear resistance also makes it suitable for use in bearings, bushings, and other similar applications.

Overall, C97600 has a unique set of physical properties that make it suitable for a wide range of applications across various industries. Its high density, high melting point, thermal and electrical conductivity, non-magnetic properties, corrosion resistance, and wear resistance make it a popular choice for many different types of projects. If you are considering using C97600 for your next project, consult with a knowledgeable supplier to ensure you are getting the right material for your specific application.

Fabrication Properties

C97600, also known as nickel silver, is a copper alloy that has excellent fabrication properties, making it a popular choice for various manufacturing applications. Understanding the fabrication properties of C97600 is crucial for those who want to determine the most suitable method for their specific application. Here are some of the key fabrication properties of C97600:

Machinability: C97600 exhibits excellent machinability, which allows for easy forming, shaping, and machining using standard methods such as cutting, drilling, and milling. This property makes it an ideal material for manufacturing intricate components and parts that require precise dimensions. It is commonly used in the manufacturing of electrical components, musical instruments, and decorative hardware.

Weldability: C97600 also has excellent weldability, which makes it easy to join with other materials using various methods such as gas tungsten arc welding, gas metal arc welding, and spot welding. Its high thermal conductivity also allows for efficient heat transfer during welding, reducing the risk of overheating and distortion.

Solderability and Brazability: Another noteworthy fabrication property of C97600 is its excellent solderability, making it easy to solder using various methods such as soft soldering and brazing. This property makes it ideal for soldering applications that require high strength and durability. It can also be joined using brazing methods, which involve heating the material to a high temperature and then joining the pieces using a filler metal that has a lower melting point than the base metal.

Formability: C97600 also has excellent formability, which allows it to be easily formed into various shapes and sizes using standard forming methods such as bending, stamping, and deep drawing. Its unique properties also allow it to be formed into intricate shapes and designs without cracking or fracturing.

Overall, C97600 is a versatile material that has excellent fabrication properties. Its easy machinability, weldability, solderability, brazability, and formability make it an ideal choice for various manufacturing applications. Whether you are in the electrical, musical instrument, or decorative hardware industry, C97600 is a material that is worth considering for your next project. Consult with a knowledgeable supplier to ensure that you are getting the right material for your specific application.

Applicable Specifications

C97600, also known as nickel silver, is a copper alloy that is commonly used in various industrial applications due to its unique properties. In order to ensure that C97600 is used appropriately, it is important to understand the applicable specifications and standards that apply to this material. Here are some of the key specifications and standards that may be applicable to C97600:

ASTM B122/B122M: This specification covers the requirements for copper-nickel-tin and copper-nickel-zinc alloys in plate, sheet, and strip form for use in general engineering applications. This specification provides guidance on the chemical composition, mechanical properties, and tolerances of C97600 material.

SAE J461: This specification covers the chemical composition, mechanical properties, and other requirements for copper alloys used in various industries, including automotive, marine, and aerospace. This specification provides guidance on the allowable limits for impurities, as well as the heat treatment requirements for C97600 material.

MIL-C-15726E: This military specification covers the requirements for copper-nickel-silicon alloy rod, bar, and wire for use in electrical applications. This specification provides guidance on the chemical composition, mechanical properties, and quality control requirements for C97600 material.

It is important to note that compliance with these specifications and standards is essential for ensuring that C97600 is used appropriately and that the finished product meets the necessary requirements for the intended application. When selecting C97600 material, it is important to work with a supplier who can provide material that meets the applicable specifications and standards, as well as any additional requirements specific to the application.

In summary, understanding the applicable specifications and standards for C97600 is essential for ensuring that this material is used appropriately in various industrial applications. ASTM B122/B122M, SAE J461, and MIL-C-15726E are just a few examples of the specifications and standards that may apply to C97600, depending on the specific application. Working with a knowledgeable supplier is essential for ensuring that the C97600 material used in your project meets the necessary requirements and specifications.

Thermal Properties of “C97600”

C97600, also known as nickel silver, is a copper alloy that possesses unique thermal properties. Understanding these properties is essential for selecting the right material for various industrial applications that involve exposure to high temperatures. Here are the key thermal properties of C97600:

Thermal conductivity: C97600 has a relatively high thermal conductivity compared to other copper alloys, making it an excellent choice for heat exchangers, radiators, and other applications that require efficient heat transfer.

Thermal expansion coefficient: C97600 has a low thermal expansion coefficient, making it suitable for applications that require dimensional stability under varying temperature conditions.

Melting point: C97600 has a high melting point of approximately 1070°C, making it suitable for high-temperature applications such as furnace components, electrical contacts, and other parts that are exposed to extreme heat.

Thermal shock resistance: C97600 has excellent thermal shock resistance, making it ideal for use in applications that involve rapid temperature fluctuations or exposure to extreme temperature gradients.

In summary, the thermal properties of C97600 make it a versatile material for use in various industrial applications that involve exposure to high temperatures. Its high thermal conductivity, low thermal expansion coefficient, high melting point, and excellent thermal shock resistance make it an ideal choice for heat exchangers, furnace components, electrical contacts, and more. When selecting C97600 for a specific application, it is important to work with a supplier who can provide material that meets the necessary specifications and standards for optimal thermal performance.

Typical Uses

C97600, commonly known as nickel silver, is a versatile copper alloy that finds its applications in various industries due to its unique properties. Let’s take a look at some typical uses of C97600:

- Electrical and Electronic Applications: C97600 is an excellent electrical conductor, making it a popular choice for electrical and electronic components, including switches, connectors, and terminals. Its high thermal conductivity and low thermal expansion coefficient also make it suitable for use in electrical contacts and heat sinks.

- Decorative Applications: C97600’s unique color, similar to that of silver, makes it a popular choice for decorative applications, including jewelry, watches, and musical instruments. Its excellent tarnish resistance ensures long-lasting shine and durability.

- Industrial Applications: Due to its high strength and corrosion resistance, C97600 is used in a wide range of industrial applications, including marine hardware, valves, and fittings. Its thermal conductivity and thermal shock resistance make it suitable for use in heat exchangers, radiator tanks, and furnace components.

- Automotive Applications: C97600 is commonly used in the automotive industry due to its excellent corrosion resistance, durability, and ease of fabrication. It is used in a wide range of automotive components, including radiator tanks, heat exchangers, and engine parts.

- Aerospace Applications: C97600’s high strength, corrosion resistance, and thermal properties make it suitable for use in various aerospace components, including fasteners, fittings, and heat exchangers.

In conclusion, C97600’s unique properties make it a versatile material for various applications across multiple industries, including electrical and electronic, decorative, industrial, automotive, and aerospace. Its high strength, corrosion resistance, thermal conductivity, and thermal shock resistance make it a preferred choice for critical applications where durability and performance are paramount. When selecting C97600 for a specific application, it is essential to work with a supplier who can provide material that meets the necessary specifications and standards for optimal performance.

Equivalents

When it comes to industrial applications, selecting the right material is crucial. C97600, or nickel silver, is a popular copper alloy that offers several beneficial properties, such as excellent thermal conductivity and thermal shock resistance. However, in some cases, C97600 may not be available or the best option for a specific use case. Luckily, there are several equivalent materials to consider that offer similar properties. Here are some of the equivalents of C97600 that you may want to consider:

C96400: This copper-nickel-silver alloy is similar to C97600 in terms of its thermal conductivity and corrosion resistance. It is an excellent alternative for applications that require these properties.

C71500: Copper nickel 70/30, also known as C71500, is an alloy with a similar thermal conductivity to C97600 and excellent resistance to corrosion and erosion. It is commonly used in marine applications, such as seawater piping, heat exchangers, and condensers.

C44300: Admiralty brass, or C44300, is a copper-zinc alloy that offers comparable thermal conductivity and thermal expansion coefficient to C97600. It is commonly used in heat exchangers, evaporator tubes, and other industrial applications.

By considering these equivalents of C97600, you can find the best material for your specific application, taking into account factors such as cost, availability, and performance requirements. Remember to consult with a supplier or materials expert to ensure that you make an informed decision.

Mechanical Properties

C97600, also known as nickel silver, is a copper alloy that is widely used in various industrial applications. One of the reasons for its popularity is its excellent mechanical properties. Let’s take a closer look at some of the mechanical properties of C97600.

Tensile strength: C97600 has a tensile strength of approximately 540 MPa, which is relatively high compared to other copper alloys. This property makes C97600 suitable for applications that require high strength and durability.

Hardness: C97600 has a hardness of around 120 Brinell, which is relatively high compared to other copper alloys. This makes it suitable for applications that require high wear resistance.

Ductility: C97600 has excellent ductility, which is the ability of a material to deform without breaking under tensile stress. This property makes it well-suited for applications that require forming or bending.

Thermal conductivity: C97600 has excellent thermal conductivity, which is the ability of a material to transfer heat. This makes it suitable for applications that require efficient heat transfer, such as heat exchangers and cooling systems.

Here is a table summarizing the mechanical properties of C97600:

| Mechanical Property | Value |

|---|---|

| Tensile Strength | Approx. 540 MPa |

| Hardness | Approx. 120 Brinell |

| Ductility | Excellent |

| Thermal Conductivity | Excellent |

In summary, C97600 is a copper alloy with excellent mechanical properties, including high tensile strength, hardness, ductility, and thermal conductivity. These properties make it well-suited for various industrial applications, such as electrical components, musical instruments, and jewelry. It’s essential to consult with a supplier or materials expert to determine if C97600 is the best option for your specific application based on the required mechanical properties and characteristics.