What is “C97800” Material

C97800 material, also known as nickel silver or German silver, is a copper-nickel-tin alloy that is widely used in various industries due to its excellent properties. This alloy contains 55-65% copper, 18-23% nickel, and 17-22% zinc, along with small amounts of lead, iron, and manganese. The addition of nickel to the alloy enhances its strength, durability, and resistance to corrosion, while the zinc content contributes to its excellent formability.

One of the main advantages of C97800 material is its high corrosion resistance. This makes it an ideal choice for many applications in the marine industry, such as shipbuilding, marine hardware, and seawater valves. Its high resistance to corrosion also makes it a popular choice in the electrical and electronic industry, where it is used to make electrical contacts, connectors, switches, and relays.

In addition to its corrosion resistance, C97800 material also has good thermal and electrical conductivity. This makes it a popular choice in the automotive industry for the production of radiators and heat exchangers, where its excellent thermal conductivity is an advantage. It is also used in the production of electrical components, where its high electrical conductivity is an important property.

C97800 material is also commonly used in the jewelry industry due to its shiny and yellowish-gray appearance. It is often used to make earrings, bracelets, and pendants, as well as other decorative items. Its good formability and workability make it an ideal choice for creating intricate designs and patterns.

Another industry that makes use of C97800 material is the musical instrument industry. The material’s excellent acoustic properties make it a popular choice for the production of musical instruments like saxophones, flutes, and trumpets. Its ability to produce high-quality sound and its durability make it an excellent choice for musicians.

In conclusion, C97800 material is a versatile copper-nickel-tin alloy with many industrial and commercial applications. Its unique combination of properties such as high corrosion resistance, good thermal and electrical conductivity, and good formability make it an ideal choice for many different applications. From marine hardware and electrical components to musical instruments and jewelry, C97800 material is a reliable and durable choice for many industries. With its ability to withstand harsh environments and its aesthetic appeal, it is a material that is likely to remain in demand for years to come.

Application Areas & Industries

C97800 material, also known as nickel silver or German silver, is a copper-nickel-tin alloy with versatile properties that make it an ideal choice for different applications across industries. In this guide, we will explore the most common application areas and industries where C97800 is used:

Marine Industry: Due to its high corrosion resistance, C97800 material is extensively used in the marine industry for applications such as marine hardware, seawater valves, and shipbuilding components. Its durability and resistance to wear and tear make it an excellent choice for these applications.

Electrical and Electronic Industry: C97800 material’s high electrical conductivity and corrosion resistance make it a popular choice for making electrical contacts, connectors, switches, and relays. These components are widely used in the electrical and electronic industry.

Jewelry Industry: C97800 material is widely used in the jewelry industry due to its shiny and yellowish-gray appearance and good formability. This alloy is commonly used to create intricate designs and patterns in items like earrings, bracelets, and pendants.

Automotive Industry: C97800 material’s excellent thermal conductivity and high corrosion resistance make it an ideal choice for the production of automotive radiators and heat exchangers. These components are essential for maintaining the optimal temperature in a vehicle’s engine.

Musical Instrument Industry: C97800 material’s excellent acoustic properties make it an ideal choice for creating high-quality sound in musical instruments like saxophones, flutes, and trumpets. This material is popular among musicians for its durability and unique sound.

In conclusion, C97800 material is a versatile alloy that finds its use in various industries for different applications. Its application areas include marine hardware, electrical and electronic components, jewelry items, automotive radiators, and musical instruments. Whether you are in the marine, electrical, jewelry, automotive, or musical instrument industry, C97800 material is a reliable and efficient choice for your projects. Always ensure you consult with a reliable supplier to get the right material for your specific application.

Common Fabrication Processes

C97800, also known as nickel silver or German silver, is a copper-nickel-tin alloy that is known for its excellent formability, corrosion resistance, and thermal and electrical conductivity. This material is widely used in various industries, including marine, electronic, automotive, and jewelry.

To manufacture different products from C97800, various fabrication processes are used. Here are some common fabrication processes of C97800:

Cold Working: Cold working is a popular process for shaping C97800 into various forms such as wires, sheets, and strips. The process involves stretching and bending the material at low temperatures to achieve the desired shape.

Hot Working: Hot working is another popular process that involves heating the material to high temperatures and then forging or rolling it into the desired shape. This process is commonly used to create complex shapes and large parts such as marine hardware and automotive parts.

Casting: Casting is a process that involves pouring molten C97800 into a mold to create the desired shape. This process is commonly used to produce decorative items and jewelry.

Machining: Machining is a process that involves cutting, drilling, and shaping the material with the help of different machines such as lathes, milling machines, and grinders. This process is used to create precise shapes and sizes for different products such as electrical contacts and connectors.

Joining: Joining is a process that involves connecting two or more pieces of C97800 material. Common joining processes include soldering and brazing, which use a filler metal to join the pieces together.

In conclusion, C97800 is a versatile material that can be shaped and formed using various fabrication processes. Whether you need to create wires, sheets, or complex shapes, the above-mentioned processes can help you achieve the desired results. However, it’s important to consult with an experienced supplier to ensure that you are using the right fabrication process for your specific application.

Additionally, it’s essential to consider the properties of C97800 when selecting the appropriate fabrication process. For example, because of its excellent thermal conductivity, hot working is often used to create automotive parts such as radiators and heat exchangers. On the other hand, cold working is more suitable for creating jewelry items because of its ability to maintain the material’s formability and luster.

By understanding the different fabrication processes for C97800, you can select the most appropriate method for your project. Working with a reputable supplier can also help ensure that you receive high-quality C97800 material that meets your specific requirements. Overall, C97800 is a highly versatile material that can be used for a variety of applications, and the right fabrication process can help you achieve the desired results for your project.

Chemical Composition

C97800, also known as nickel silver or German silver, is a copper-nickel-tin alloy that is widely used in various industries due to its excellent formability, corrosion resistance, and thermal and electrical conductivity. The chemical composition of C97800 is carefully controlled to achieve the desired properties and characteristics for specific applications.

Here’s a table summarizing the chemical composition of C97800:

| Element | Percentage |

|---|---|

| Copper | 55-65% |

| Nickel | 17-23% |

| Zinc | 16-24% |

| Lead | 0.05% max |

| Iron | 0.05% max |

| Manganese | 0.50% max |

| Silicon | 0.10% max |

| Antimony | 0.25% max |

| Phosphorus | 0.15% max |

| Sulfur | 0.08% max |

As you can see from the table, copper is the main component of C97800, followed by nickel and zinc. Other elements, such as lead, iron, and manganese, are present in smaller quantities to provide additional properties such as improved machinability or increased strength. The precise amount of each element in the alloy can vary slightly depending on the specific application.

In conclusion, the chemical composition of C97800 is carefully controlled to achieve the desired properties and characteristics for specific applications. By understanding the composition of C97800, manufacturers can select the right alloy for their needs and ensure that their products meet the required standards and regulations.

Physical Properties

C97800, also known as nickel silver or German silver, is a copper-nickel-tin alloy that exhibits excellent physical properties. This material is highly sought after for its unique combination of strength, ductility, and corrosion resistance. In this guide, we will explore the physical properties of C97800 in more detail:

Density: The density of C97800 is 8.83 g/cm³, which is slightly less than pure copper. This makes it a good choice for applications where weight is a concern.

Melting point: C97800 has a high melting point of around 1100°C (2012°F). This makes it suitable for high-temperature applications such as furnace components and heating elements.

Thermal conductivity: C97800 has high thermal conductivity, making it an ideal choice for applications that require the efficient transfer of heat. It is commonly used in electronic devices and heat exchangers.

Electrical conductivity: C97800 is an excellent conductor of electricity, with a conductivity even higher than pure copper. This makes it a popular choice for electrical applications such as connectors, switches, and terminals.

Magnetic properties: C97800 is non-magnetic, which makes it an ideal material for applications where magnetic interference can be a problem.

Corrosion resistance: C97800 exhibits excellent corrosion resistance, particularly in marine environments. This is due in part to its high copper content, which makes it an excellent choice for marine hardware, shipbuilding, and other similar applications.

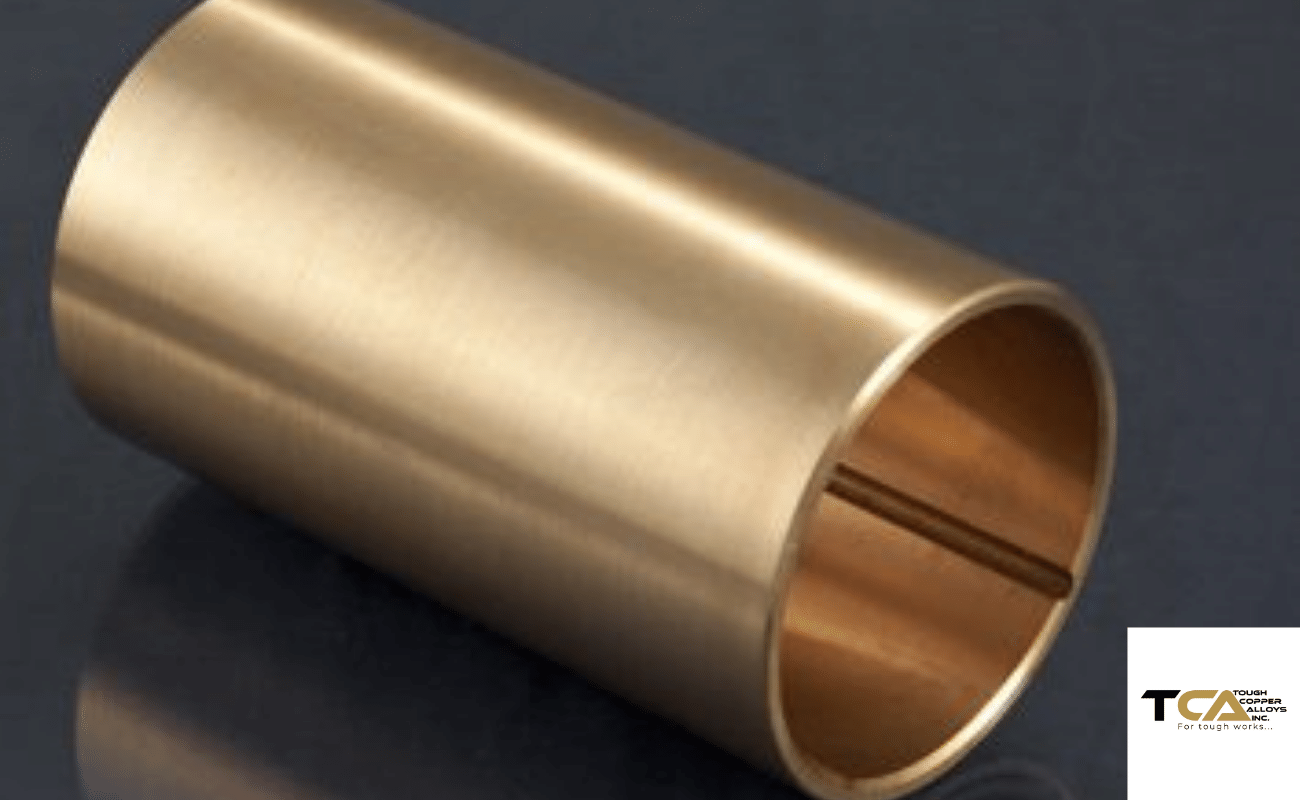

Wear resistance: C97800 has good wear resistance, making it suitable for use in bearings, bushings, and other similar applications.

Overall, the physical properties of C97800 make it a highly versatile material that can be used in a wide range of applications. Its high thermal and electrical conductivity, non-magnetic properties, corrosion resistance, and wear resistance make it an excellent choice for many different types of projects. If you are considering using C97800 for your next project, consult with a knowledgeable supplier to ensure you are getting the right material for your specific application.

And here is a table summarizing the physical properties of C97800:

| Property | Value |

|---|---|

| Density | 8.83 g/cm³ |

| Melting point | 1100°C |

| Thermal conductivity | High |

| Electrical conductivity | Excellent |

| Magnetic properties | Non-magnetic |

| Corrosion resistance | Excellent |

| Wear resistance | Good |

Fabrication Propertes

C97800, also known as nickel silver or German silver, is a copper-nickel-tin alloy that is known for its excellent physical properties. In addition to its desirable physical characteristics, C97800 is also known for its exceptional fabrication properties. Understanding these properties is essential for those who want to determine the most suitable method for their specific application. Here are some of the key fabrication properties of C97800:

Machinability: C97800 exhibits excellent machinability, making it easy to machine and shape using various cutting and drilling tools. This property makes it ideal for complex parts and components that require precise dimensions. It can be used in the manufacturing of musical instruments, electrical components, and decorative hardware.

Weldability: C97800 also has good weldability, allowing it to be easily joined with other materials using proper welding techniques and procedures. Its high thermal conductivity allows for efficient heat transfer during welding, reducing the risk of overheating and distortion.

Brazability and Solderability: C97800 can be effectively joined using various brazing and soldering techniques. This property makes it a versatile material for different fabrication applications that require strong and durable bonds. It can be used in the manufacturing of jewelry, silverware, and plumbing fixtures.

Formability: C97800 has good formability, making it easy to form into various shapes and sizes using a range of bending and forming techniques. This property makes it a versatile material for different fabrication applications that require specific shapes and designs.

Overall, the fabrication properties of C97800 make it a popular choice for a variety of industries and applications. Its excellent machinability, weldability, brazing and soldering properties, and formability make it a versatile material that can be easily formed and fabricated to meet specific project requirements. Whether you are in the jewelry, plumbing, or musical instrument industry, C97800 is a material that is worth considering for your next project. Consult with a knowledgeable supplier to ensure that you are getting the right material for your specific application.

Applicable Specifications

C97800, also known as nickel silver or German silver, is a copper-nickel-tin alloy that is widely used in various industrial applications due to its excellent physical and mechanical properties. To ensure that C97800 meets the required standards and specifications, it is important to use the appropriate specifications for this material.

Here are some of the most common specifications used for C97800:

ASTM B151: This specification covers copper-nickel-tin alloy plates, sheets, and strips. It outlines the chemical composition requirements and mechanical properties, such as tensile strength, yield strength, and elongation, of C97800.

ASTM B121: This specification covers copper-nickel-tin alloys in the form of seamless tubes for heat exchangers and condensers. It provides guidance on the chemical composition, mechanical properties, and manufacturing process requirements of C97800 tubes.

AMS 4510: This specification covers nickel silver bars, rods, and shapes. It sets out the requirements for the chemical composition, mechanical properties, and manufacturing process of C97800 bars, rods, and shapes.

Other specifications that may be applicable to C97800 include ISO 1338, JIS H3100, and EN 1652. These specifications provide guidelines for the chemical composition, mechanical properties, and manufacturing processes of copper-nickel-tin alloys.

When selecting C97800 material, it is important to work with a knowledgeable supplier who can provide material that meets the applicable specifications and standards, as well as any additional requirements specific to the application. By using the appropriate specifications, you can ensure that C97800 will perform well and meet your expectations in your industrial application.

Thermal Properties of “C97800”

C97800, also known as nickel silver or German silver, is a copper-nickel-tin alloy that possesses excellent thermal properties. These properties make it ideal for use in various applications that require materials to withstand high temperatures and thermal stress. Here are the key thermal properties of C97800:

Thermal conductivity: While the thermal conductivity of C97800 is relatively low compared to other metals, such as copper and aluminum, it is still high enough to make it a suitable material for heat transfer applications. The thermal conductivity of C97800 is around 20 W/mK at room temperature.

Coefficient of thermal expansion: C97800 has a relatively low coefficient of thermal expansion, which means that it can withstand thermal stress without significant deformation or cracking. The coefficient of thermal expansion of C97800 is around 17.8 x 10^-6 m/mK at room temperature.

Melting point: C97800 has a high melting point of around 1,070°C, which makes it suitable for use in high-temperature applications. Its melting point is comparable to that of other copper alloys and some grades of stainless steel.

It is important to note that C97800 may exhibit different thermal properties depending on the specific alloy composition and manufacturing process. Therefore, it is essential to consult with a knowledgeable supplier to determine the best C97800 material for a particular application.

In summary, C97800 has excellent thermal properties, including a relatively high thermal conductivity, low coefficient of thermal expansion, and high melting point. These properties make it suitable for use in various applications that require materials to withstand high temperatures and thermal stress. To ensure optimal thermal performance, it is crucial to work with a supplier who can provide material that meets the necessary specifications and standards.

Typical Uses

C97800, also known as nickel silver or German silver, is a versatile copper-nickel-tin alloy that has a wide range of industrial applications. Its unique combination of strength, ductility, and thermal properties make it a popular choice for various applications across different industries.

Here are some typical uses of C97800:

- Electrical components: C97800 is often used in the manufacturing of electrical components, such as switches, relays, and connectors, due to its excellent electrical conductivity and corrosion resistance.

- Musical instruments: C97800 is a popular material for musical instruments, particularly brass instruments, due to its excellent acoustic properties and durability. It is often used in the manufacturing of trumpet and trombone mouthpieces, saxophones, and other brass instruments.

- Jewelry: C97800 is a popular material for jewelry due to its attractive color and durability. It is often used in the manufacturing of high-quality silverware, silver-plated items, and costume jewelry.

- Heat exchangers: C97800’s thermal properties make it an ideal material for use in heat exchangers, such as radiators, HVAC systems, and other applications that require efficient heat transfer.

- Marine applications: C97800’s resistance to corrosion makes it a popular choice for marine applications, such as shipbuilding, marine hardware, and other applications that involve exposure to saltwater and harsh environmental conditions.

In conclusion, C97800 is a versatile material that finds application in various industries due to its unique properties. Its uses include electrical components, musical instruments, jewelry, heat exchangers, and marine applications. When selecting C97800 for a particular application, it is important to work with a supplier who can provide the necessary material specifications and standards for optimal performance.

Equivalents

When it comes to copper-nickel-tin alloys, C97800, also known as nickel silver or German silver, is a popular choice for its excellent thermal properties and corrosion resistance. However, in some cases, C97800 may not be available or the best option for a particular use case. Here are some equivalents of C97800 that you may want to consider:

C77000: Nickel silver 18%, or C77000, has a similar composition to C97800 but with slightly different amounts of nickel and zinc. It offers good corrosion resistance, moderate strength, and excellent malleability and ductility, making it suitable for various applications, including electrical components, jewelry, and musical instruments.

C74500: Nickel silver 12%, or C74500, has a lower nickel content than C97800 and a higher zinc content, which gives it better corrosion resistance but lower electrical conductivity. It is often used in marine applications, decorative trim, and architectural hardware.

C93200: SAE 660 bronze, or C93200, is a copper-tin alloy that offers excellent wear resistance, high strength, and good corrosion resistance. It is commonly used in bearings, bushings, and other mechanical applications.

C70600 and C71500: Copper-nickel alloys, such as C70600 and C71500, offer excellent corrosion resistance in seawater and other harsh environments. These alloys are often used in marine applications, heat exchangers, and piping systems.

By considering these equivalents of C97800, you can find the best material for your specific application, taking into account factors such as cost, availability, and performance requirements. Remember to consult with a supplier or materials expert to ensure that you make an informed decision.

Mechanical Properties

C97800, also known as nickel silver or German silver, is a copper-nickel-tin alloy that is widely used in various applications due to its excellent mechanical properties. In this article, we will focus on the mechanical properties of C97800 and present a table summarizing its characteristics.

Tensile Strength: The tensile strength of C97800 ranges from 370 to 655 MPa, depending on the temper of the alloy. This means that C97800 is resistant to deformation under tension and can withstand a significant amount of stress without breaking.

Yield Strength: The yield strength of C97800 is 170 MPa. This is the stress at which the material begins to deform plastically and is no longer able to return to its original shape.

Elongation: The elongation of C97800 is 40%. This is the amount of deformation that the material can undergo before it fractures. This high elongation makes C97800 an excellent choice for applications where the material will be subjected to repeated bending or vibration.

Hardness: The hardness of C97800 ranges from 80 to 130 HB, depending on the temper of the alloy. This is a measure of the material’s resistance to indentation or scratching.

Modulus of Elasticity: The modulus of elasticity of C97800 ranges from 130 to 150 GPa, depending on the temper of the alloy. This is a measure of the material’s stiffness, or how much it will deform when subjected to a given load.

Table summarizing the mechanical properties of C97800:

| Property | Value |

|---|---|

| Tensile Strength | 370-655 MPa (54,000-95,000 psi) |

| Yield Strength | 170-345 MPa (25,000-50,000 psi) |

| Elongation | 5-40% |

| Hardness | 70-130 HB |

| Modulus of Elasticity | 120-140 GPa (17,000-20,000 ksi) |

| Thermal Conductivity | 40-70 W/mK |

| Coefficient of Thermal Expansion | 17.7-18.6 µm/m°C (9.8-10.3 µin/in°F) |

In conclusion, C97800 is a copper-nickel-tin alloy that exhibits excellent mechanical properties, including high tensile and yield strengths, good ductility and malleability, excellent thermal conductivity, and good corrosion resistance. Its high elongation and modulus of elasticity make it suitable for applications where the material will be subjected to repeated bending or vibration. If you are looking for a material with these properties, consider C97800 as an option.