What is “C86200” Material?

C86200 is a bronze alloy that consists of copper, zinc, tin, and lead. It belongs to the family of high-strength phosphor bronzes and is also known as SAE 430B bronze. This material is highly valued for its superior mechanical properties, excellent wear resistance, and high corrosion resistance.

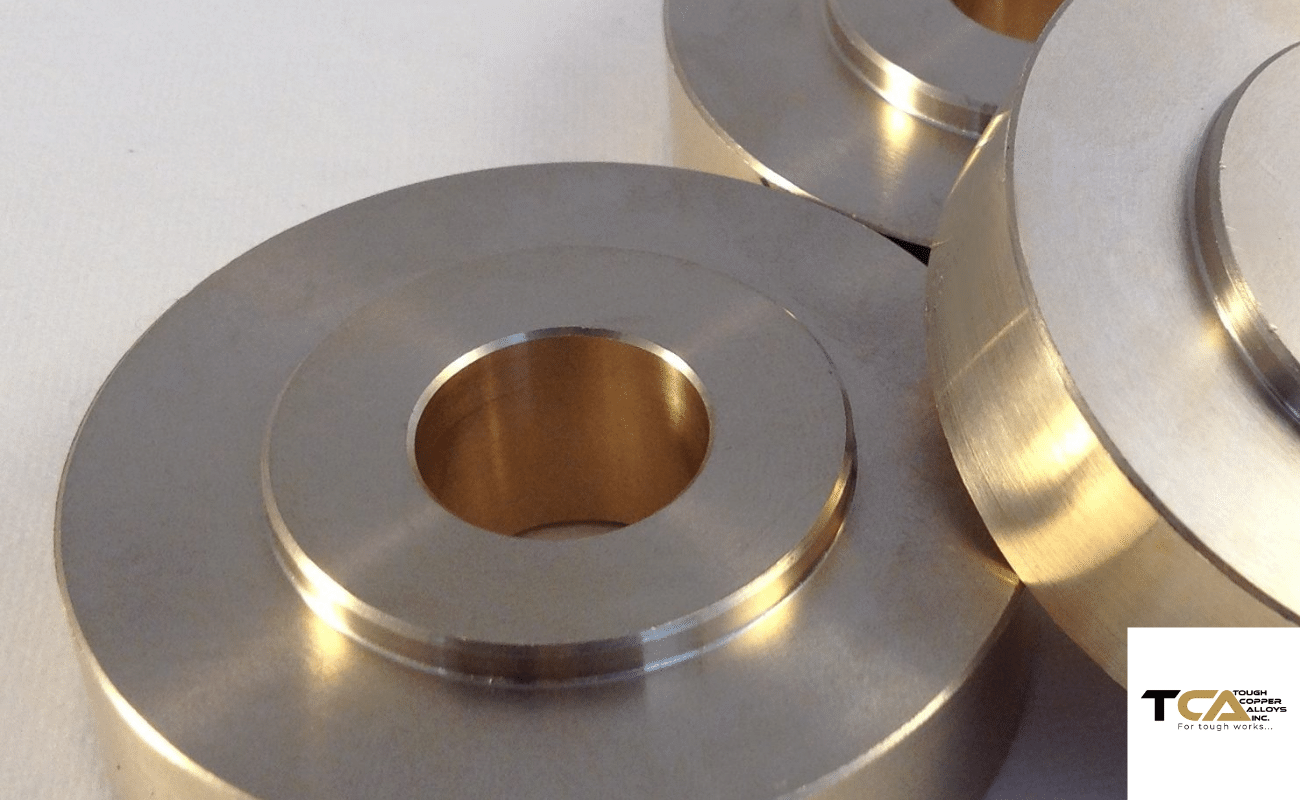

One of the key benefits of C86200 is its exceptional machinability, which makes it a popular choice for various industrial applications. It can be easily shaped into complex geometries using standard machining techniques, such as drilling, turning, milling, and grinding. This makes C86200 an ideal material for the manufacture of precision parts, including bearings, bushings, gears, valve stems, and other components that require high dimensional accuracy and reliability.

Apart from its machinability, C86200 offers excellent strength and durability. Its high tensile and yield strength make it suitable for use in applications that require resistance to heavy loads, shock, and vibration. Furthermore, its excellent wear resistance enables it to withstand repeated abrasion and friction, making it ideal for use in high-wear environments.

Another significant advantage of C86200 is its outstanding corrosion resistance. This material exhibits exceptional resistance to a wide range of corrosive agents, including seawater, acids, alkalis, and organic compounds. As a result, it is widely used in marine, aerospace, and chemical processing applications where components must withstand harsh environments.

C86200 is also a highly cost-effective material, thanks to its excellent performance-to-cost ratio. Its low melting point and good casting properties make it an ideal choice for casting processes, such as sand casting, investment casting, and continuous casting. This makes it possible to produce large quantities of components in a cost-effective manner.

In conclusion, C86200 is a versatile, high-performance material that offers exceptional machinability, strength, wear resistance, and corrosion resistance. Its ability to deliver outstanding performance under harsh conditions makes it an excellent choice for a wide range of industrial applications. Whether you are looking for a material that can withstand heavy loads, resist wear and tear, or resist corrosion, C86200 is an ideal choice that is sure to meet your needs.

Application Areas & Industries

C86200, also known as SAE 430B bronze, is a high-performance bronze alloy that finds applications in various industries. This material is valued for its excellent mechanical properties, including high strength, wear resistance, and corrosion resistance. Here are some of the application areas and industries where C86200 is commonly used:

- Aerospace Industry: C86200 is used in the aerospace industry to manufacture a wide range of components, including bearings, gears, valve stems, and other critical parts. Its high strength and excellent wear resistance make it an ideal material for use in aircraft engines and landing gear.

- Marine Industry: C86200 is highly resistant to corrosion and is, therefore, a popular choice for marine applications. It is used to manufacture components such as propellers, shafts, and valves that are exposed to seawater and other corrosive agents.

- Oil and Gas Industry: C86200 is used in the oil and gas industry to manufacture components such as valve bodies, pump housings, and flanges. Its high strength and excellent corrosion resistance make it well-suited for use in harsh oil and gas environments.

- Automotive Industry: C86200 is used in the automotive industry to manufacture components such as bearings, bushings, and gears. Its high wear resistance and excellent machinability make it an ideal material for use in transmission systems, engine components, and suspension systems.

- Industrial Machinery: C86200 is used in various industrial machinery applications, including mining equipment, heavy machinery, and construction equipment. Its high strength and excellent wear resistance make it well-suited for use in high-stress applications.

- Electrical Industry: C86200 is used in the electrical industry to manufacture components such as connectors, contacts, and switches. Its high electrical conductivity and excellent corrosion resistance make it an ideal material for use in electrical applications.

In conclusion, C86200 is a versatile and high-performance material that finds applications in various industries. Its exceptional mechanical properties, including high strength, wear resistance, and corrosion resistance, make it an ideal choice for use in demanding environments. Whether you are looking for a material for use in the aerospace, marine, oil and gas, automotive, industrial machinery, or electrical industry, C86200 is an excellent choice that is sure to deliver outstanding performance and durability.

Common Fabrication Processes

C86200, also known as SAE 430B bronze, is a high-strength phosphor bronze alloy that is commonly used in various industries for its superior mechanical properties. This material is highly valued for its excellent wear resistance, high strength, and outstanding corrosion resistance. Here are some of the most common fabrication processes used for C86200:

- Casting: C86200 is often cast into complex shapes using sand casting, investment casting, or continuous casting processes. The low melting point and good casting properties of C86200 make it easy to produce large quantities of components in a cost-effective manner.

- Machining: C86200 has excellent machinability and can be easily shaped into complex geometries using standard machining techniques such as drilling, turning, milling, and grinding. This makes it an ideal material for the manufacture of precision parts, including bearings, bushings, gears, and valve stems.

- Cold Working: C86200 can be cold worked by processes such as bending, coining, and stamping to produce components with specific shapes and dimensions. Cold working can also improve the strength and hardness of C86200, making it more suitable for high-stress applications.

- Welding: C86200 can be welded using various welding processes such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. However, welding should be performed with care to avoid reducing the material’s strength and toughness.

- Heat Treatment: C86200 can be heat-treated to improve its strength and hardness. Common heat treatment processes for C86200 include annealing, normalizing, and quenching and tempering.

In conclusion, C86200 is a versatile material that can be fabricated using various processes to meet the specific requirements of different applications. Its excellent machinability, wear resistance, and corrosion resistance make it an ideal choice for the manufacture of precision components that require high dimensional accuracy and reliability. Whether you need to cast, machine, cold work, weld, or heat-treat C86200, this material offers a wide range of fabrication options that can help you achieve your desired outcome.

Chemical Composition

C86200, also known as SAE 430B bronze, is a high-performance phosphor bronze alloy that is widely used in various industries for its exceptional mechanical properties. This material is highly valued for its high strength, wear resistance, and outstanding corrosion resistance. Here is a breakdown of the chemical composition of C86200:

| Element | Composition % |

|---|---|

| Copper (Cu) | 63.0 – 68.0 |

| Lead (Pb) | 2.5 – 4.0 |

| Tin (Sn) | 0.20 – 0.50 |

| Zinc (Zn) | 25.0 – 30.0 |

| Phosphorus (P) | 0.03 – 0.35 |

Copper (Cu) is the main component of C86200, accounting for 63.0 – 68.0% of the material. Copper gives C86200 its high strength and excellent corrosion resistance. Lead (Pb) and Tin (Sn) are added to the alloy to improve its machinability, while Zinc (Zn) is added to improve its strength and hardness. Phosphorus (P) is also present in C86200 as a deoxidizing agent.

The chemical composition of C86200 makes it an excellent material for use in various high-stress applications, including aerospace, marine, oil and gas, automotive, industrial machinery, and electrical industry. Its high strength and wear resistance make it well-suited for use in components that are subjected to heavy loads and frequent wear, while its outstanding corrosion resistance makes it an ideal choice for use in harsh environments.

In conclusion, C86200 is a high-performance phosphor bronze alloy with a unique chemical composition that offers superior mechanical properties. Its excellent strength, wear resistance, and corrosion resistance make it an ideal choice for use in various industrial applications. Whether you are looking for a material for use in aerospace, marine, oil and gas, automotive, industrial machinery, or electrical industry, C86200 is an excellent choice that is sure to deliver exceptional performance and durability.

Physical Properties

C86200, also known as SAE 430B bronze, is a high-strength phosphor bronze alloy that is widely used in various industries for its superior mechanical properties. In addition to its excellent chemical composition, C86200 also exhibits impressive physical properties that make it an ideal choice for use in high-stress applications. Here are some of the key physical properties of C86200:

- Density: The density of C86200 is around 8.8 g/cm3, which is relatively high compared to other materials. This high density gives C86200 its excellent strength and toughness, making it ideal for use in components that are subjected to heavy loads and frequent wear.

- Melting point: The melting point of C86200 is around 995°C (1823°F). This low melting point makes it easy to cast and fabricate C86200 using various processes, including sand casting, investment casting, and continuous casting.

- Thermal conductivity: The thermal conductivity of C86200 is around 47 W/mK. This high thermal conductivity makes C86200 an excellent material for use in heat exchangers, radiators, and other components that require efficient heat transfer.

- Electrical conductivity: The electrical conductivity of C86200 is around 10% IACS (International Annealed Copper Standard). This high electrical conductivity makes C86200 an excellent material for use in electrical components that require high conductivity and low resistance.

- Hardness: The hardness of C86200 ranges from 110 to 140 Brinell hardness (HB). This high hardness gives C86200 excellent wear resistance, making it ideal for use in components that are subjected to frequent wear and abrasion.

- Corrosion resistance: C86200 exhibits excellent corrosion resistance, particularly in marine and seawater environments. This makes it an ideal choice for use in components that are exposed to corrosive elements.

In conclusion, C86200 is a versatile material with impressive physical properties that make it an excellent choice for use in various high-stress applications. Its high density, low melting point, high thermal and electrical conductivity, high hardness, and excellent corrosion resistance make it a top choice for use in a range of industries, including aerospace, marine, oil and gas, automotive, industrial machinery, and electrical industry.

Fabrication Properties

C86200, also known as SAE 430B bronze, is a high-performance phosphor bronze alloy that is widely used in various industries for its excellent mechanical properties. In addition to its chemical and physical properties, C86200 also exhibits impressive fabrication properties that make it easy to work with and process. Here are some of the key fabrication properties of C86200:

- Machinability: C86200 has excellent machinability, thanks to the presence of lead and tin in its chemical composition. This makes it easy to machine and fabricate using various processes, including drilling, tapping, turning, milling, and grinding.

- Weldability: C86200 is generally considered to be weldable using various welding techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. However, preheating and post-weld heat treatment may be necessary to prevent cracking and ensure good weld quality.

- Formability: C86200 can be easily formed using various processes, including cold working, hot working, and forging. However, due to its high strength and hardness, it may require higher forming pressures and temperatures compared to other materials.

- Casting: C86200 is an excellent material for casting due to its low melting point, good fluidity, and excellent castability. It can be cast using various casting processes, including sand casting, investment casting, and continuous casting.

- Surface finish: C86200 has excellent surface finish properties, allowing it to achieve a high-quality surface finish after various machining and surface treatment processes. This makes it an ideal choice for use in components that require a high-quality finish.

In conclusion, C86200 is a versatile material with impressive fabrication properties that make it easy to work with and process. Its excellent machinability, weldability, formability, castability, and surface finish properties make it an ideal choice for use in various industrial applications. Whether you are looking for a material for use in aerospace, marine, oil and gas, automotive, industrial machinery, or electrical industry, C86200 is an excellent choice that is sure to deliver exceptional performance and durability.

Applicable Specifications

C86200, also known as SAE 430B bronze, is a high-strength phosphor bronze alloy that is widely used in various industries for its superior mechanical properties. To ensure its quality and performance, C86200 is manufactured in compliance with several applicable specifications and standards. Here are some of the most commonly used specifications for C86200:

- ASTM B505: This specification covers the standard requirements for C86200 bronze rod, bar, and shapes. The specification covers the chemical composition, mechanical properties, and other requirements for C86200 products.

- SAE J461: This specification covers the chemical composition, mechanical properties, and other requirements for various copper alloys, including C86200. The specification covers the different grades of copper alloys and their corresponding properties.

- AMS 4862: This specification covers the requirements for C86200 bronze sand castings. The specification covers the chemical composition, mechanical properties, and other requirements for C86200 sand castings.

- MIL-B-11553: This specification covers the requirements for C86200 bronze ingots and castings. The specification covers the chemical composition, mechanical properties, and other requirements for C86200 products used in military applications.

- QQ-C-390: This specification covers the requirements for various bronze alloys, including C86200. The specification covers the chemical composition, mechanical properties, and other requirements for different bronze alloys used in various industrial applications.

In conclusion, C86200 is a high-performance phosphor bronze alloy that is manufactured in compliance with various applicable specifications and standards. The ASTM B505, SAE J461, AMS 4862, MIL-B-11553, and QQ-C-390 are some of the most commonly used specifications for C86200. By using materials manufactured in compliance with these specifications, you can ensure that your components will deliver exceptional performance and durability in various industrial applications.

Thermal Properties

C86200, also known as SAE 430B bronze, is a high-strength phosphor bronze alloy that offers excellent mechanical properties, making it suitable for use in various industrial applications. In addition to its mechanical properties, C86200 also exhibits impressive thermal properties, making it a preferred material for high-temperature applications. Here are some of the key thermal properties of C86200:

- Thermal conductivity: C86200 has a high thermal conductivity, making it an excellent conductor of heat. This property enables it to transfer heat quickly and efficiently, making it an ideal material for use in heat exchangers, radiators, and other similar applications.

- Thermal expansion: C86200 has a low coefficient of thermal expansion, which means that it can withstand thermal stresses and thermal cycling without deforming or cracking. This property makes it an ideal choice for use in components that are subjected to high-temperature variations.

- Melting point: C86200 has a relatively low melting point of approximately 1000°C. This property makes it easy to cast and shape into different forms, including rods, bars, and castings.

- Specific heat capacity: C86200 has a moderate specific heat capacity, which means that it can store and release heat efficiently. This property makes it suitable for use in thermal energy storage applications.

- Thermal stability: C86200 exhibits excellent thermal stability, which means that it can maintain its properties even when exposed to high temperatures for extended periods. This property makes it an ideal material for use in high-temperature applications, such as furnace parts, boilers, and heat exchangers.

In conclusion, C86200 is a high-performance phosphor bronze alloy that exhibits impressive thermal properties, making it an ideal material for use in various high-temperature applications. Its high thermal conductivity, low coefficient of thermal expansion, moderate specific heat capacity, low melting point, and excellent thermal stability make it a preferred material for use in heat exchangers, boilers, furnace parts, and other similar applications. Whether you are looking for a material for use in aerospace, marine, oil and gas, automotive, industrial machinery, or electrical industry, C86200 is an excellent choice that is sure to deliver exceptional performance and durability.

Typical Uses

C86200, also known as SAE 430B bronze, is a high-strength phosphor bronze alloy that is widely used in various industries due to its superior mechanical and thermal properties. Its excellent corrosion resistance, wear resistance, and machinability make it an ideal material for a wide range of applications. Here are some of the typical uses of C86200:

- Bearings: C86200 is widely used in the production of high-load bearings due to its excellent wear resistance, fatigue resistance, and low coefficient of friction. Bearings made of C86200 are commonly used in industrial machinery, automotive engines, and marine equipment.

- Gears: C86200 is an ideal material for the production of gears due to its high strength, hardness, and wear resistance. Gears made of C86200 are commonly used in industrial machinery, automotive transmissions, and marine propulsion systems.

- Valve components: C86200 is widely used in the production of valve components, such as valve bodies, stems, and seats, due to its excellent corrosion resistance, machinability, and thermal properties. Valves made of C86200 are commonly used in various industries, including oil and gas, chemical processing, and power generation.

- Electrical connectors: C86200 is an excellent material for use in electrical connectors due to its high electrical conductivity and corrosion resistance. Electrical connectors made of C86200 are commonly used in various electronic devices, including computers, televisions, and telecommunications equipment.

- Fasteners: C86200 is an ideal material for use in the production of fasteners, such as screws, bolts, and nuts, due to its excellent mechanical properties and corrosion resistance. Fasteners made of C86200 are commonly used in various industries, including construction, automotive, and aerospace.

In conclusion, C86200 is a high-performance phosphor bronze alloy that is widely used in various industries due to its superior mechanical and thermal properties. Its typical uses include bearings, gears, valve components, electrical connectors, and fasteners, among others. Whether you are looking for a material for use in industrial machinery, automotive engines, marine equipment, electrical devices, or any other application, C86200 is an excellent choice that is sure to deliver exceptional performance and durability.

Equivalents

C86200 is a high-strength phosphor bronze alloy that is widely used in various industries due to its superior mechanical and thermal properties. It is a well-established material that has been in use for decades and has a number of equivalent materials available on the market. Here are some of the common equivalents of C86200:

- ASTM B505 Alloy C86200: This is the standard specification for C86200 phosphor bronze alloy rod, bar, and shapes. It is widely used in various applications, including bearings, gears, valve components, and fasteners.

- SAE 430B: This is the SAE designation for C86200 phosphor bronze alloy. It is a high-strength material that is commonly used in industrial machinery, automotive engines, and marine equipment.

- JIS C 5341: This is the Japanese Industrial Standard for C86200 phosphor bronze alloy. It specifies the chemical composition, mechanical properties, and other characteristics of the material.

- DIN 17662: This is the German standard for C86200 phosphor bronze alloy. It specifies the chemical composition, mechanical properties, and other characteristics of the material.

- BS PB104: This is the British standard for C86200 phosphor bronze alloy. It specifies the chemical composition, mechanical properties, and other characteristics of the material.

In conclusion, C86200 is a high-performance phosphor bronze alloy that has a number of equivalents available on the market. These include ASTM B505 Alloy C86200, SAE 430B, JIS C 5341, DIN 17662, and BS PB104. Whether you are looking for a specific standard or need to choose an equivalent material for your application, there are many options available to suit your needs.

Mechanical Properties

C86200 is a high-strength phosphor bronze alloy that exhibits excellent mechanical properties, making it a popular choice for various industrial applications. Here are the mechanical properties of C86200:

- Tensile Strength: C86200 has a tensile strength of 110 ksi (758 MPa). This is the maximum stress that the material can withstand while being pulled or stretched before it breaks.

- Yield Strength: C86200 has a yield strength of 62 ksi (427 MPa). This is the stress level at which the material starts to deform plastically, or permanently, when being pulled or stretched.

- Elongation: C86200 has an elongation of 10%. This is the amount of deformation the material can undergo before breaking or rupturing.

- Hardness: C86200 has a Brinell hardness of 210. This is a measure of the material’s resistance to indentation or penetration by a hard ball.

- Fatigue Strength: C86200 has excellent fatigue strength, making it suitable for applications subjected to cyclic loading or stress.

These mechanical properties make C86200 a strong and durable material that can withstand heavy loads and high stresses. It is commonly used in applications such as bearings, gears, valve components, and fasteners, where strength and durability are critical. In addition, its excellent fatigue strength makes it ideal for applications subjected to repeated stresses, such as in the aerospace and automotive industries. Overall, C86200 is a reliable and versatile material with impressive mechanical properties.